The need to replace the engine timing chain does not arise often, but for shops it can represent a very profitable operation.

While automotive timing chains are usually designed to last the life of the vehicle, there are times when they will need to be replaced. In fact, a determining factor in the premature wear of this key part is preventive maintenance, especially regular lubricant changes and replacement of filters with good quality products. Remember that the timing chain, which has largely replaced the serpentine belt, is essential to the proper operation of the engine.

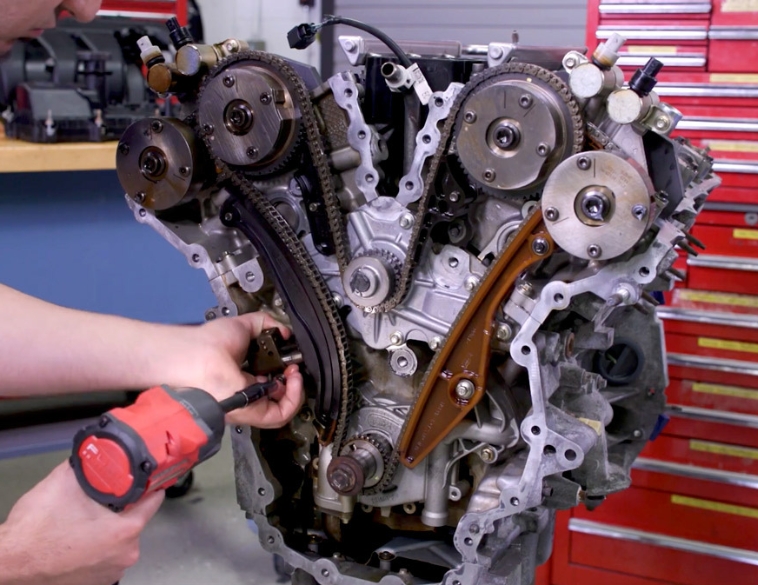

Jay Buckley, Director of Product Management at Dayco Aftermarket, confirms that although these chains are typically designed to last the life of the vehicle, there are times when the shop needs to address issues related to them. “Excessive chain noise or rubbing from the engine can indicate worn chain shoes or tensioners. On the other hand, a P016 fault code on the engine management module (ECM), which is the most common, indicates a timing problem between the cam and crankshaft sensors resulting from chain wear or elongation.”

The condition of the engine

Certainly, before considering replacing a timing chain, it is essential to check the overall condition of the engine. Replacement is not recommended on an engine that is poorly maintained, has low compression or oil pressure, or is leaking. It would be a waste of time and money.

Because replacing a timing chain is a costly operation. “The time required to replace this part and its accompanying accessories will vary from vehicle to vehicle,” Buckley says. “On some front-wheel drive models, the engine must be removed from the vehicle to complete the replacement. Typically, the job will take anywhere from 4 to 21 hours. When done by a qualified technician, it’s very cost-effective for the shop.”

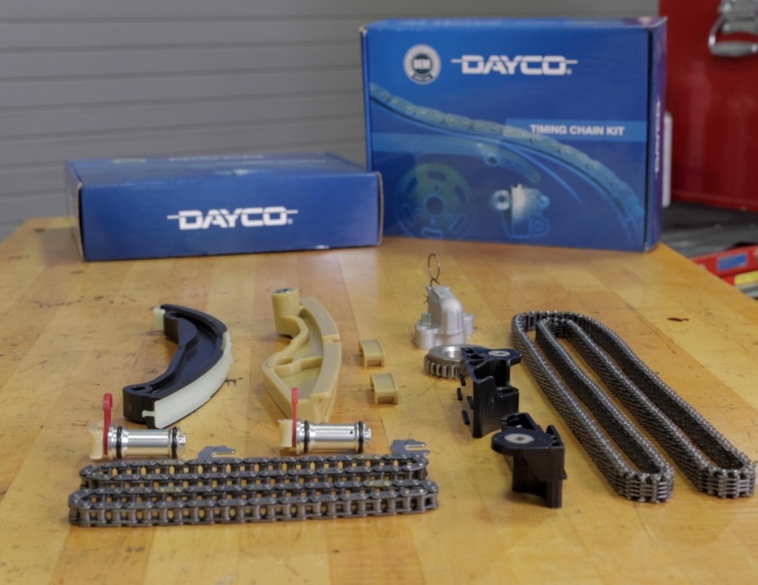

Most specialized suppliers have developed complete solutions for the replacement of timing chains and their accessories. These sets include the chain as well as the necessary pads, tensioners and sprockets. As the Dayco specialist points out, “There’s only one right way to replace that chain, and that’s to do it by changing all the parts that go with it as well.” Dayco Aftermarket features kits that cover 87 percent of vehicles and 100 percent of engines that have demonstrated a weakness in this area.

Help for the technician

To help the technicians in charge of carrying out this delicate operation, the suppliers of replacement parts have filmed technical support capsules on their website to guide them, step by step. Dayco also features a QR code on each box of its replacement timing chain kits that leads the technician directly to installation instructions specifically for that vehicle.

Schaeffler, through its INA brand, also offers high-quality timing chain assemblies. In some cases the proposed set includes more than one chain. This is especially true for this supplier, which is presenting a complete kit including three chains, guides and sprockets for GM’s high-performance 3.6-liter V6 engine.

The complete approach

Speaking at the AAPEX show in Las Vegas, Ryan Smith, director of product category management for Cloyes, said the automotive aftermarket has realized the importance of offering complete timing chain replacement packages to shops.

“With the proliferation of timing chains in place of serpentine belts at automakers, we’re also seeing an increase in the complexity of parts,” says Ryan Smith. “For one replacement, you can have up to 26 separate components. Our advice is to replace them at the same time you replace the chain, to avoid problems in the future. Replacing the chain without the complementary parts means risking the return of a dissatisfied customer and the resumption of an expensive job for the shop. That’s why we deliver complete assemblies to get the job done right, without customer feedback.”

Smith realizes that replacing these key parts to manage the engine and its accessories is not a simple task. That’s why Cloyes also supports technicians with tips on how to effectively replace these parts on its YouTube channel.