Modern solutions for fixing modern panels

While dents and creases on exterior body panels can be a frustration for consumers, repairing them can be highly lucrative for collision centres. In today’s era of high inflation, high-interest rates and continued supply chain disruptions, a repair-first strategy is considered essential for well-run collision centres. With people keeping vehicles longer and used vehicles in high demand, dent repair is a critical part of that strategy and good quality, versatile equipment is essential. Here we look at some premium offerings currently available on the market.

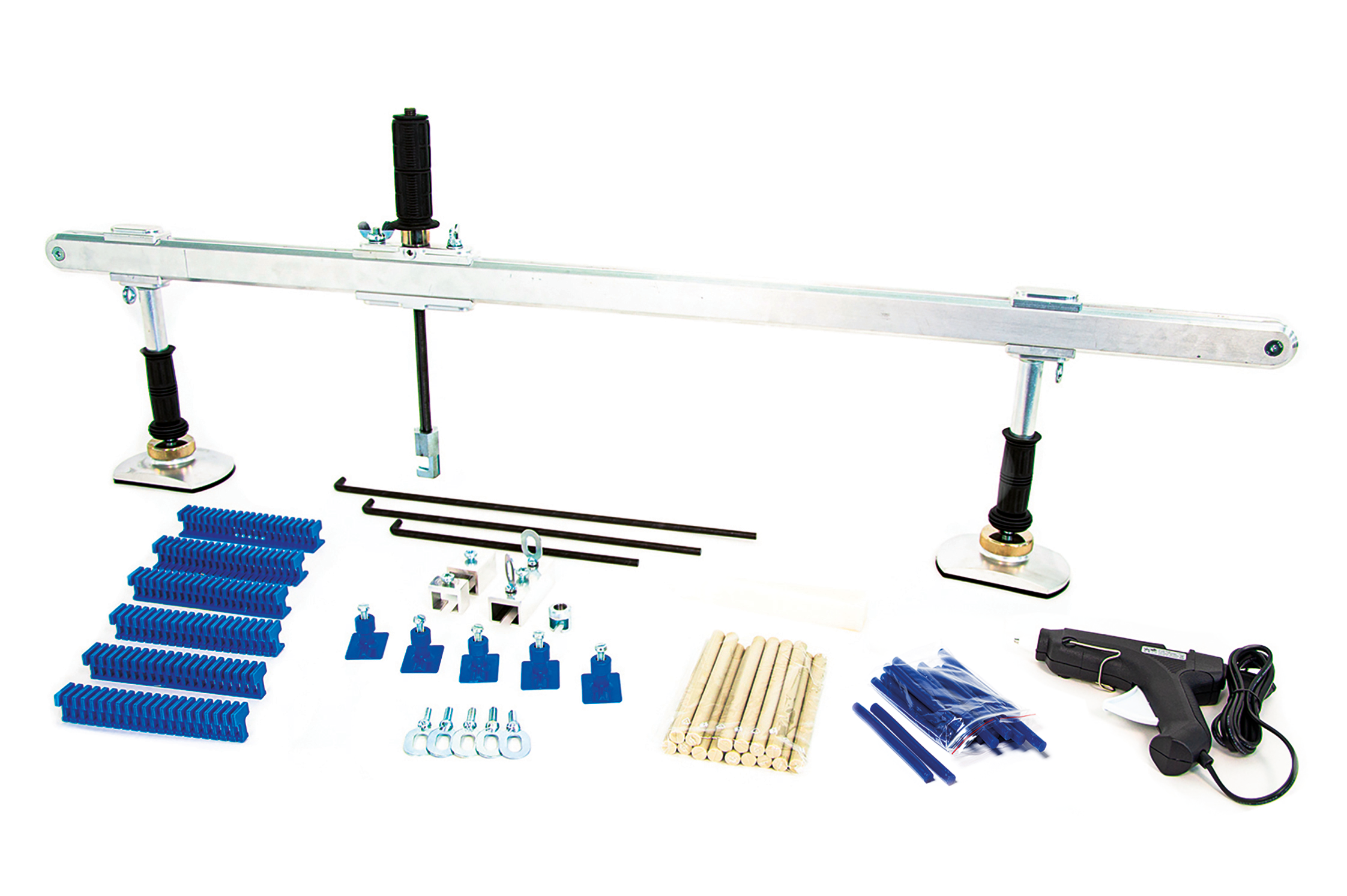

BETAG Speedline Business System

BETAG’s Speedline Business System comes with all the tools needed to repair medium damage on vehicle panels fast and efficiently. It comes with six different Speedline tools, as well as Power Knobs for stronger pulling on the panel, as well as the required adhesive and glue gun, as well as three different types of pulling elements and an adjustable Bridge. Technicians can perform repairs by using adhesive from the glue gun attached to the Speedline which is placed over and pressed and secured onto the damaged area of the vehicle. Applying the Bridge and the tension-relieving crowns over the Speedline enables faster dent pulling. Changing the pulling element will impact the area where the dent is being pulled. On medium damage repairs, the Bridge and Speedline can remove most of the damage, leaving light repairs which can be done using Power Knobs. The Speedline and Power Knobs also have suitable pulling force for large-area glue panel repairs.

Chief Multitool Workstation with M35

An easy-to-handle, mobile workstation cabinet designed for dedicated dent repair, tool storage and serving as a workbench, Chief’s Multitool Workstation is specifically aimed at repairing aluminum and sheet steel panels.

The workstation includes a 115-volt M35 Drawn ARC Welder with an automatic gun, two ground electrodes, aluminum keys, a consumables box and a lifting rod. It also features a 90 cm anodized aluminum pulling bar kit with mobile feet and 10×10 cm pivoting bases. The feet have a unique shape and design with suction cups, which will enable them to easily fit into the vehicle’s exterior, including sharp and angular panel surfaces. The mobile workstation also comes with 3-tie-rods and multi-hook gripping heads for a combined or independent dent-pulling task. For smaller repairs, the workstation comes with an anodized aluminum pulling system with a single tie-rod that features special heads for pulling either single or multiple hooks. A circular base accessory can be used in place of the feet for repairing small-diameter dents. The workstation also comes with four different anodized aluminum hammers (Round head 3.2 and 6.7 oz units, as well as a 6.7 oz square head and a 20.8 oz mallet.

The kit also includes a heat gun for use on the dented area of the aluminum panel that needs to be repaired, as well as a heat shield that protects the parts of the panel not subject to repair. An angled air die grinder is also provided as a dedicated tool to eliminate cross-contamination during the aluminum repair. There’s also a start kit comprising aluminum studs and zinc-plated steel eye bolts, with a plastic holding case.

Pro Spot Aluminum, Steel and Glue Dent Repair Station

Designed as a professional solution for complete dent repair needs, the MWS-GTK-AL-ST dent repair station comes with a whole host of dent-pulling tools and accessories. These include the Pro Spot PR-3 Auto Steel Dent Puller, DA-3 Dent Pulling System and PRO-GTK Glue Tab kit.

The PR-3 Auto generates precise current and time, preventing damage and corrosion on the back side of the workspace. The PR-3 automatically senses when the pull key makes contact with the surface material and welds the key to the precise piece being repaired.

The PRO-GTK Glue Tab Dent Repair Kit, aids the dent repair process by avoiding welding and arc procedures, saving time. The kit works on directly painted aluminum and steel surfaces and has multiple style pull accessories for any dent and reusable Pull Tabs. Using it doesn’t require panel removal and it eliminates any workspace backside burn through damage or corrosion.

The workstation can be used anywhere within the shop environment and features plenty of storage space, enabling aluminum and steel tools to be stored separately.