The new generations of spectrophotometers allow body shops to gain time and precision when choosing paint for refinishing work.

As Angela Simon, Director of Innovation Marketing at Sherwin-Williams explains, the spectrophotometer is a colour measurement tool for choosing the best formula to match the colour already on the vehicle.

“The spectrophotometer is faster and simpler than the manual selection process, almost as easy as taking a picture with a smartphone. In comparison, the traditional method requires a trained technician to refer to sample boxes and compare them to the body under proper lighting.”

According to Simon, the spectrophotometer is commonly used in European workshops.

She confirms that its adoption is growing in North America, especially since the new models are easier to use, more powerful and less expensive than previous technologies.

An adjustment in the workshop

For Natalie M. Scott, Director of Marketing, Colour, and Allen Porter, Director of Digital Products, at PPG Automotive Paint, the spectrophotometer requires a gradual adaptation by the shop.

“For us, we are in the third generation of this tool, which has improved in accuracy and ease of use,” says Scott.

“There is still a cultural adjustment in bringing it into the shop. Some technicians like to hold a paint sample in their hand to validate their colour choice.”

At the other end of the spectrum, some shops will rely totally on the device’s reading, leaving the sample box behind.

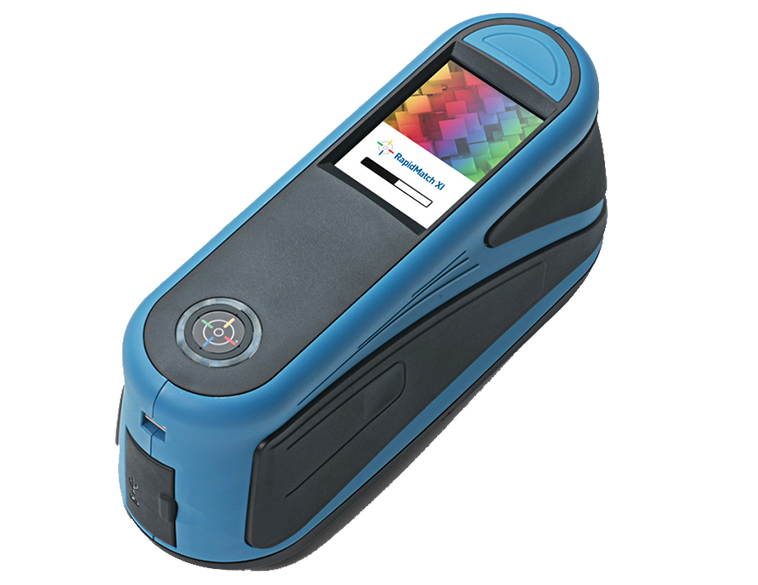

“A well-cleaned and polished surface combined with image capture using our RapidMatch XI tool, which provides access to our constantly updated 3.5 million-colour digital database, produces a highly accurate result that will blend seamlessly with the rest of the body,” says Porter.

This colour bank is updated regularly, offering a speed advantage over sample boxes that are updated more sporadically.

As they both point out, even if a manufacturer introduces a new colour with its own code, it does not mean that it will be an exact match from one factory to another.

PPG Automotive Paint specialists document all these variants, analyze them, and add the formulation to the central colour database quickly.

“The value of the spectrophotometer is directly related to the richness of our colour bank,” Scott says. “If you want an accurate tool, it needs to guide you to the most accurate colour possible.”

“The more a technician works with the instrument, puts it through its paces, validates the results, and develops expertise and confidence in the spectrophotometer’s results,” Porter says.

“That’s where there will be real savings, reducing cycle time by accelerating the time it takes to find the right colour variant.”

Sharing the information

To facilitate the introduction of this tool in the workshops that are not yet equipped with it, PPG Automotive Paint has an information and training program that starts with the members of its sales force and goes on to the workshops.

“We train our sales force and our distributors, who in turn give the information to workshop managers and their technicians. And we are always on hand to answer questions from all these partners,” explain the two PPG representatives.

Dispose of samples

If you have to consider a certain investment to acquire the spectrophotometer, the sample boxes are also expensive.

The ability to eliminate them should be a goal for the workshop. But for the transition to be smooth, the shop needs to take ownership of the tool.

“It’s not an infallible tool,” says Normand Cormier, Director of Classroom Training for North America at Axalta Coating Systems. “You have to use it on every vehicle to get good. The camera is not going to fix everything.”

To be on the safe side and to get a feel for this new process, Cormier recommends preparing a validation card with the colour found by the spectrophotometer in the digital colour bank accessible by the tool.

“You can validate the proposal and even see the result on the screen,” explains the expert.

Knowing how to prepare

The spectrophotometer offers several advantages over sample boxes.

The formula database is constantly updated, unlike the colour boxes which are updated twice a year.

The tool should be regularly cleaned and calibrated, and the reading surface well cleaned and polished.

“You should also choose a reading area close to the part to be repainted,” advises Cormier.

“The colour on a vehicle is rarely equal from one part of the body to another. You have to take this into account if you want a nice blend.”

For Normand Cormier, the adoption of this technology, which has been around for a long time but has become much simpler in recent years, is a generational factor.

“Many of our workshops use both the spectrophotometer and the sample boxes. The new generation relies solely on the digital tool they have learned to master.”

It should be noted that paint suppliers provide training and guidance to facilitate the transition to this tool.