Panel discussion focused on welding and ADAS practices, training, equipment, and specialization

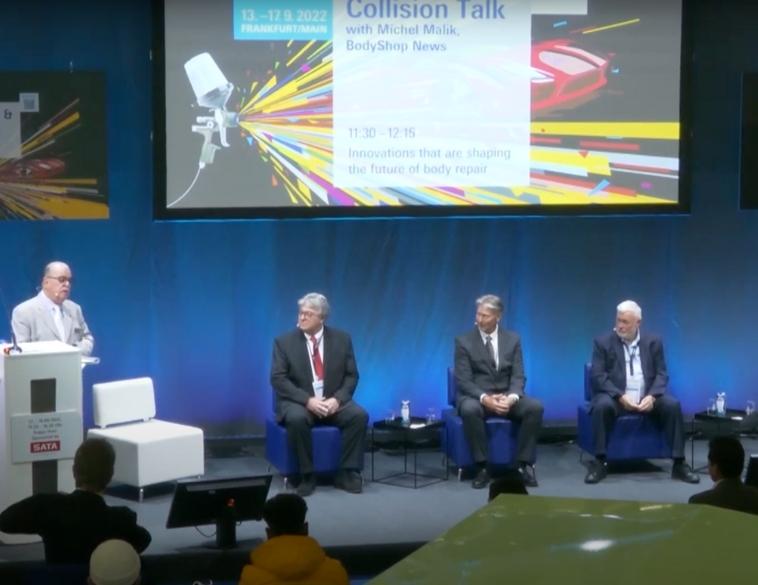

During this year’s Automechanika Frankfurt Expo, a special Collision Talk panel discussion was hosted on September 16. The event, emceed by Michel Malik, publisher of Body Shop News, brought together some leading minds from the global collision repair sector to discuss innovations that are shaping the future of the industry.

The panel discussion featured Pierre Nicolau, President & CEO of Celette; Ron Olsson, President & CEO of Pro Spot International; Osvaldo Bergaglio, CEO of Symach; and Robert Snook, President of MG Cannon, a major UK-based multi-shop operator (MSO).

Changes in welding technology

The first topic of discussion centred around innovation in welding technology. Ron Olsson, noted that given the proliferation in the types of different substrates used in modern vehicles, the way in which repairs are conducted has changed significantly. Olson noted that when it comes to welding, the emphasis is on using equipment that is smarter, more efficient, and easier to use. Welding algorithms and documentation are absolutely essential to ensure repairs are performed correctly and the vehicle is returned to true pre-crash condition.

Because vehicle technology is changing so fast and OEMs can introduce multiple updates and changes both to the vehicle and repair procedures during the course of a year, it’s important that today’s welding equipment can receive updates and information on new repair procedures, via WiFi technology that’s built right into it.

The logging and tracking of information and the ability to access it is therefore an essential and integral part of modern welding practices within the collision shop environment.

Energy conservation

Energy costs are another prime consideration for collision centres today and in Europe, skyrocketing electricity and gas costs have the industry looking for ways to conserve energy usage. Osvaldo Bergaglio; said that having solid, repeatable processes are key to making energy savings work on a sustainable and consistent level. On the drying side, for example, Bergaglio noted that for a process such as UV drying, which can reduce the curing time of the paint finish, it is essential to have a process in place, otherwise, the shop can’t realize the true benefits of employing this technology.

Advanced Driver Assist System (ADAS) calibration is becoming an increasingly important part of the modern collision repair process, yet as Robert Snook explained, many collision centres aren’t properly equipped to perform it properly. “We’re just starting to see the first 360-calibration requirements,” Snook stated, but in most cases, he said shops don’t often have the space to perform them. “You need a 15 x 9 m area that’s well-lit and with a flat floor.” He noted that many current collision facilities operate in 8 x 4 m spaces, and particularly in large city centres where space is at a premium, performing ADAS calibrations is going to prove challenging.

Snook said that many shops are trying to get around this issue by creating a calibration space at the front of the shop, in the main thoroughfare of the shop, because in most cases, they’re just performing front-facing radar calibrations. With 360-degree calibrations increasingly required, more space is needed and most shops simply can’t afford to have a vehicle blocking the gangway for nine hours while calibrations are performed.

Fewer repairs, higher costs

Looking at repair profiles and structural repairs, Pierre Nicolau explained that while fewer collisions happen today due to the growth in the adoption of ADAS technology, the damage from each tends to be more extensive, due to materials and sensors employed on many vehicles. As a result, the cost per repair has increased significantly, due to the complexity and accuracy required in making sure a vehicle is properly straightened and aligned, as well as the scanning and calibration required to ensure it performs correctly. Additionally, because the repair process and the tools required are more complex, technician skills have also had to change to adapt to this new reality. “Today it is very important that we try to simplify the tools needed for the repair process,” said Nicolau. “Technicians need to focus more on the repair process itself than on the tools they use.”

Training practices are also a key factor in modern collision shop operations. Ron Olsson noted that a big challenge is making sure technicians are able to train and learn at the right time. Building training tutorial videos into the equipment is one approach Pro Spot has used to help with this issue, while programs offered by organizations like I-CAR in the U.S. and Canada can provide huge benefits for shops and technicians that enroll in them.

Olsson also noted that with technician turnover tending to be high in the industry, the ability for new hires to learn as quickly as possible is essential. This is one reason why Pro Spot has invested heavily in offering tutorials on its welding equipment and WiFi connectivity that allows the programming to be regularly updated so technicians have access to the latest OEM repair requirements.

Given Symach’s innovative approach to collision shop processes, the company has also invested very heavily in training. Its REMO platform uses a movie script format to teach not only how to use the equipment but how to spray and apply primer, paint, clear, and body filler. “The main issue many shops have is not with the technicians, but with the managers and owners that are not training-oriented,” said Osvaldo Bergaglio. He explained that training is only as good as those that choose to implement it and for consistent results, there needs to be consistency in maintaining training, not reverting to old habits once the equipment has been installed.

The future of collision repairs

During the session, members of the audience were invited to ask questions. One that generated a lot of interest was about the future of collision repair procedures. Pierre Nicolau noted that today, less than a quarter of all repair procedures are performed accurately and correctly worldwide. Given how quickly automotive technology is advancing and along with it, the collision repair process, accuracy, and ease-of-use of equipment will be absolutely paramount to ensure success moving forward. The shops that don’t adopt this strategy, simply won’t survive.

Osvaldo Bergaglio added that complexity will also require further specialization when it comes to the repair process. This means shops in the future will likely focus on more specific brands of vehicles and specific types of repair. Bergaglio said that volume will often be a factor. “Those shops that have the volume will need to decide on the types of repairs they perform, such as repairing prestige vehicles, doing reconditioning work, repairing classic cars, or commercial vehicles and RVs.”

Robert Snook concurred, noting that the idea of a collision centre fixing all makes and models and performing all kinds of body repairs is quickly becoming a thing of the past, with more and more shops choosing to specialize and turn away work that doesn’t fit their repair profile or area of expertise.