Timing chain supplier Cloyes is ramping up innovative approaches to help technicians replace this critical part.

As Barry Harris, vice president of business development for Cloyes, points out, mechanics need to understand that an engine can be repaired.

“As far as our specialty goes, blockchain, it’s an accessible job for a good technician and a paying project for the shop,” he explains.

As he notes, nearly 75 percent of vehicles on the road today are equipped with a timing chain, replacing the belts that dominated the market in previous years.

And 90% of the vehicles on the manufacturers’ assembly lines contain them.

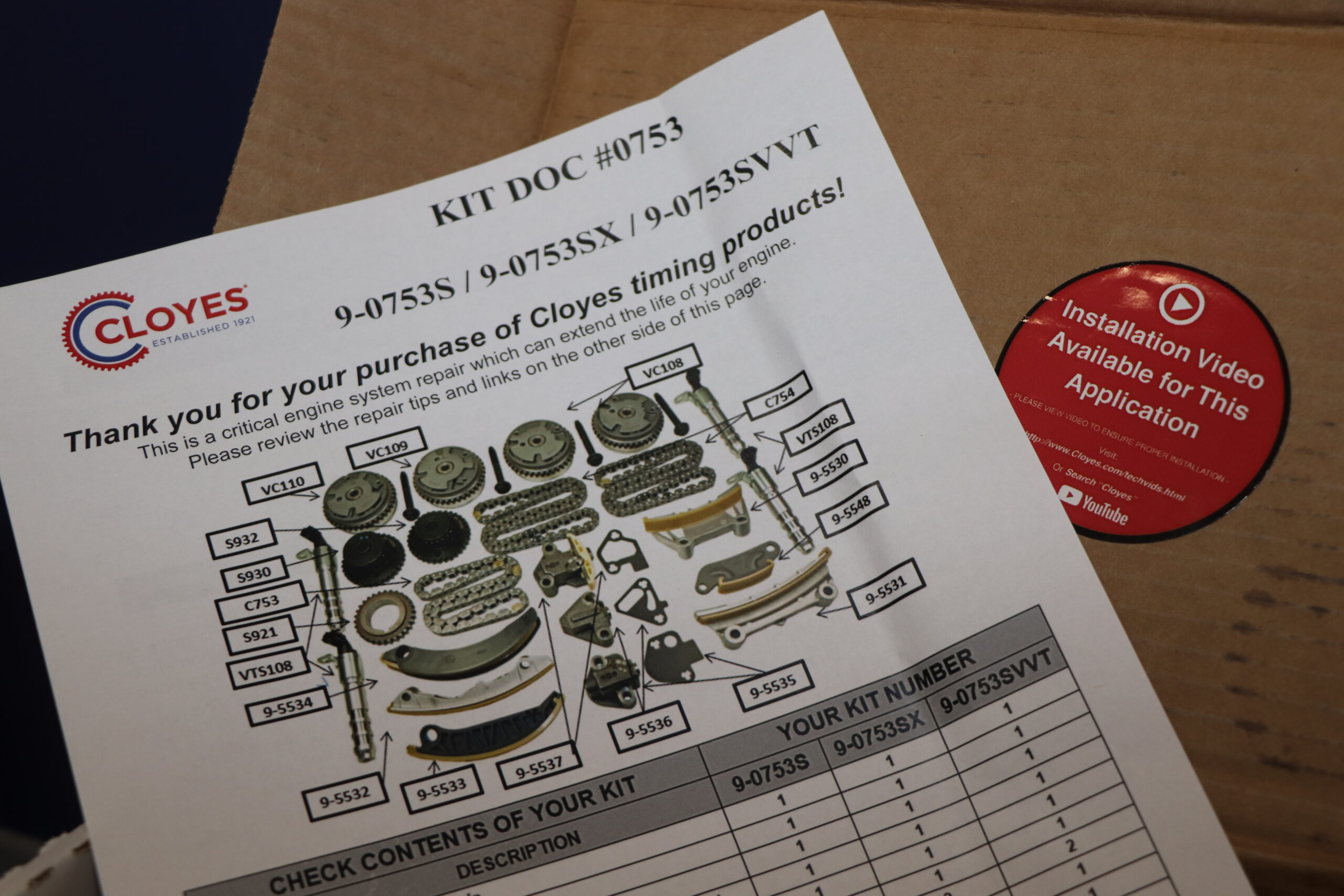

Of course, Cloyes is continually introducing new replacement chains and all related accessories.

“The replacement may also require changing several secondary parts,” explains the expert, “and we make sure that the technician will find in the box, exactly everything he needs to do the job.”

To support the technicians, Cloyes has set up a training program, the Shop Master.

This platform, designed for technicians by technicians, guides them, through short videos, to very specific solutions.

An advisory committee made up of mechanics is consulted for the preparation of training content, as well as for the analysis of parts sets to ensure that nothing is missing.