Uneven compression leads to valve train fix.

We received a call to look at a 2018 Jeep Wrangler with a 3.6L engine.

We observed that the engine was rough but there was no flashing CEL light nor were there any codes stored in the PCM.

The engine was rough enough that I thought that the misfire counters should have been clocking up but all we were able to notice was the odd single count on random cylinders.

Clearly below the PCM’s misfire threshold, however what misfires we did see were on bank 1.

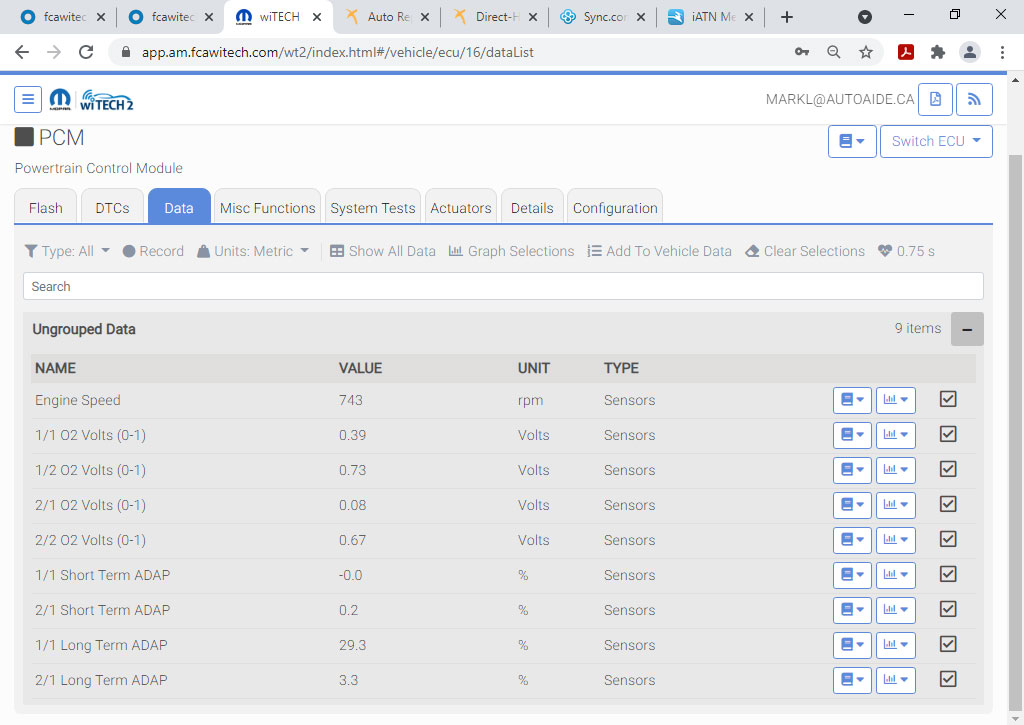

We then decided to look at the fuel trims to see if there was an actual problem that was worth chasing.

As you can see by the trims, bank 1 is adding fuel which is indicative of a misfire or at least, incomplete combustion. A quick check of spark and fuel injection action revealed no faults.

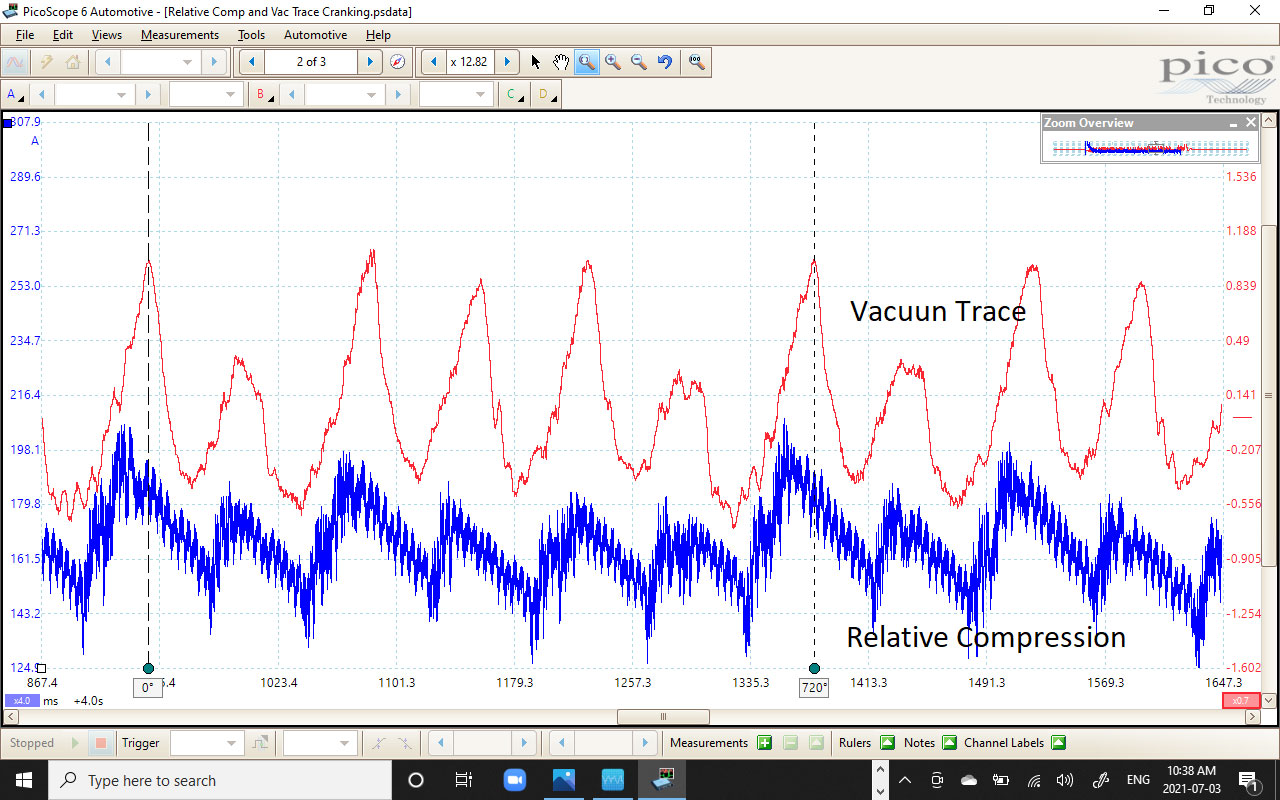

Vacuum trace

We decided to do a quick vacuum trace on the intake and a relative compression test to check the mechanical integrity of the engine.

These are simple tests that involve hooking a pressure transducer to the brake booster vacuum hose and a current probe around the battery cable and cranking the engine.

As you can see, the vacuum trace clearly shows a mechanical defect in that two of the vacuum pulls are weaker than the rest and two of the cylinders appear to have higher compression.

If you are not used to using vacuum transducers even though the problem is clear in the trace, the problem is not severe but does indicate an issue with engine’s ability to pump air. This is reinforced with the relative compression trace.

Now the question becomes, what can cause a weak vacuum pull and high compression while at the same time cause the engine to run rough? We decided to do an in-cylinder pressure transducer test on the bank 1 cylinders.

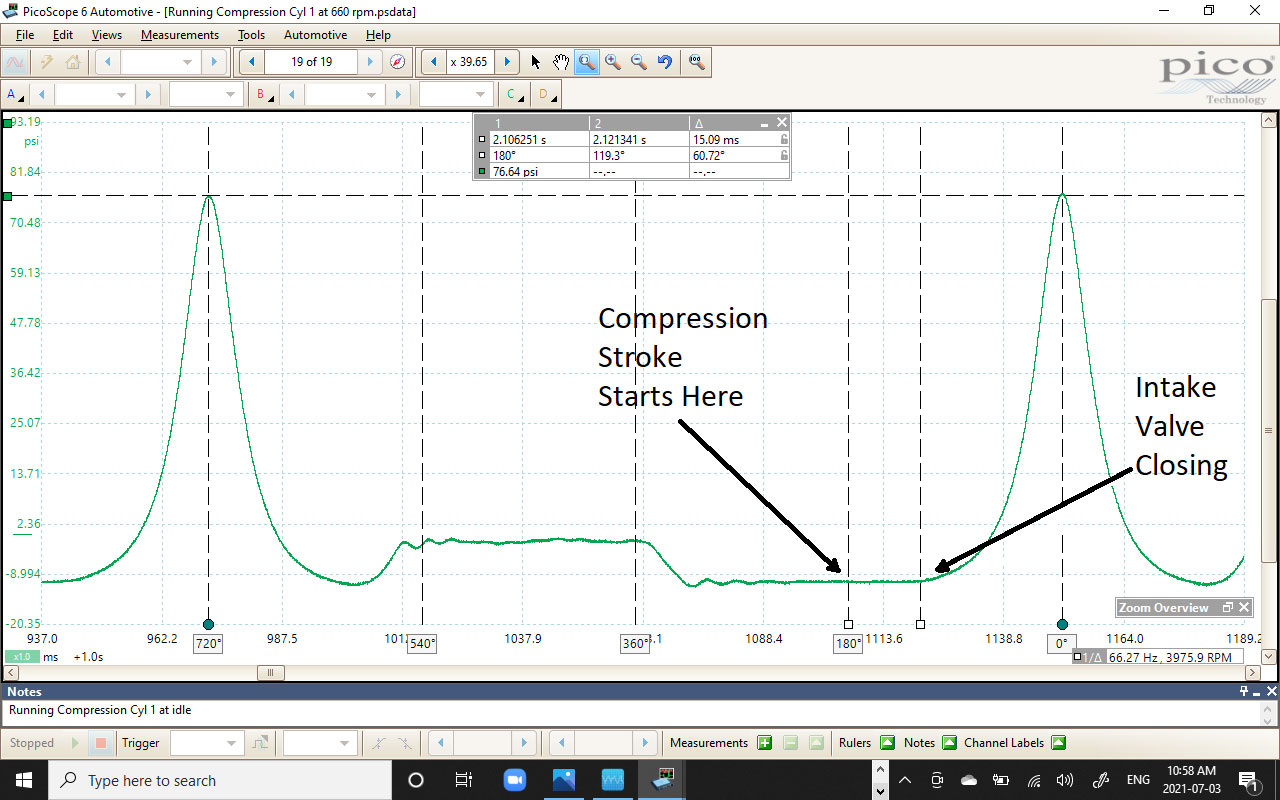

Figure 3 shows the trace from cylinder 1. We are particularly interested in the IVC (Intake Valve Closing) event. All readings were taken at 600 RPM with the camshaft VVT actuators disconnected.

As can be observed in figure 3, the IVC event is happening at 60 degrees after Bottom Dead Centre (BDC) of the compression stroke and was making just over 75 psi compression.

We then compared that to a cylinder that had normal compression. We observed 65 psi compression and IVO at 75 degrees after BDC of the compression stroke.

Not a timing issue

The intake valve on cylinder 1 was closing 15 degrees early on cylinder 1.

So, what is going on here?

The intake valve on cylinder 1 is closing too early. This caused the intake stroke to be longer, resulting in higher compression. It also means that the cylinder is not being scavenged properly, resulting in the slight misfire and the high fuel trim on bank 1.

We observed this on cylinders 1 and 5. We know this is not a camshaft timing issue because cylinder 3 (which is on the same bank), tested normal.

From here the question becomes, what can cause the intake valve to close too early?

It must be either the roller rocker or the camshaft lobes are worn. We sent the vehicle back to the shop for tear down and were informed that the camshaft had worn lobes.

The final fix was a new camshaft and lifters

Mark Lemay is President of Auto Aide Technical Services. You can reach him at [email protected]