What happened? Around thirteen years ago, on March 11, 2011, a tsunami triggered by an earthquake in Japan led to an accident at the Fukushima nuclear power plant in Japan.

At the time, Merck’s Onahama plant was the only one in the world to manufacture xirallic pearls.

Unfortunately, the dangers of radiation mean that a 30-kilometer safety zone has been set up around the nuclear power plant, and the Merck plant is within this zone. The worldwide supply of these pearlescent pigments is therefore interrupted for a period of around three months.

While this may seem a short time, the impact is quickly being felt in the industry. Ford and Chrysler have to restrict the availability of certain red and black colours on their new cars, for example. At Hyundai, the solution chosen is to replace the xirallics pearls with conventional pearl pigments in their colours, which greatly modifies their appearance.

Repair shops are also affected. For a certain period, it will no longer be possible to order these colorants for their mixing system. As the xirallics pigment inventory is very limited, distributors will mix colours in-store and send them to workshops to avoid unused material sleeping on a shelf.

The difference between a conventional pearl pigment and a xirallic pigment?

The main differences between the two pigments are their composition, the shape of the pigment and the way light reacts with them.

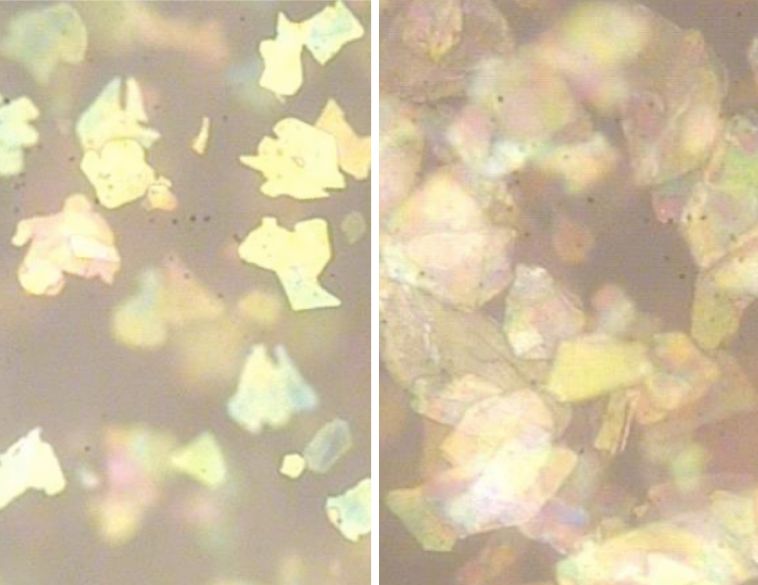

Conventional pearl pigments are generally of organic origin and are produced by grinding mica. Their brilliance is less pronounced, but they come in a wider range of colours and sizes than xirallics. They can exhibit color interference which, depending on the angle of observation, can create totally different colors. They may have a “milky” or yellowish appearance when viewed from the side.

A product that’s easier to use

Xirallics pigments, on the other hand, are made from a flat sheet of aluminum oxide with perfectly similar surfaces that are highly reflective under intense light. The automotive finish sparkles when light is shone directly on the surface. The smaller size of xiral pigments makes them easier to use, as they can create a sparkling effect without having to be larger, like conventional pearl pigments. Their properties enable pure effects even on white vehicles. Their high level of transparency also makes them ideal for darker colours.

These pigments increase the saturation of a colour. In other words, red xirallic pigment in an intermediate coat applied to a three-coat red vehicle, for example, will make the vehicle’s colour purer and more intense.

Automotive manufacturers now use practically only these to achieve effects that will appeal to consumers thanks to their saturation, as well as their powerful, extremely pure brilliance.

Let’s hope a disaster like Fukushima never happens again, for everyone’s sake!

LAVAL

LAVAL Full time

Full time