The replacement and calibration of components for advanced driver assistance systems (ADAS) is gradually creeping into collision shops’ operations. The question is, how can these operations be profitable?

The investment in equipment and training required to bring a workshop up to speed is substantial. What’s more, calibration requires space and specific conditions, necessitating the reorganization of premises where physically possible.

Faced with this situation, many collision shops will be forced to outsource these calibrations to subcontractors, notably dealerships. This has an impact on production flows, quality control and revenue management.

A logical approach

“Obviously, we had no choice but to move in this direction,” explains Jean-François Gratton, Owner of CARSTAR shop in Dégelis. “The dealerships are a long way from our shop, and it was a waste of time and revenue to have the cars transported there. We had already developed an expertise in calibration, since we’ve been replacing car windows for five years. Replacing a windshield often requires adjustments to the camera that sits behind it. Building on this expertise, we gradually introduced ADAS-related calibrations into our collision repair processes. We have proceeded logically, targeting the makes and models most present in our market. We have no choice: the industry is moving in this direction. And the longer a workshop waits, the more it’s going to cost to get up to speed.”

At present, the workshop is able to carry out 80% of the necessary calibrations on the vehicles entrusted to it. Like all things, the first ones took longer, but with time the operation has become much simpler.

“When it comes to profitability, it’s hard to give a clear answer today,” admits Gratton. “I can say that there is hope. The situation has changed, since we have large volumes of vehicles to repair, which changes our relationship with insurers. Some offer fixed prices, others understand that we charge more; one thing’s for sure, we can discuss things more easily, especially as all our processes are well documented according to the manufacturers’ requirements. Insurers need to recognize our efforts and investments.”

For the Dégelis shop, performing calibrations in-house already represents a saving compared to outsourcing them to others.

Greater efficiency

Corey Etheridge, Co-Owner of the Fix Auto shop in Fredericton, New Brunswick, integrated ADAS calibrations more recently for reasons similar to those mentioned by his colleague. We wanted to reduce waiting times,” he explains. It’s also important to be able to do this work in-house, knowing that the industry is moving in this direction.”

He estimates that around 20% of the cars to be repaired in his workshop require one or more calibrations. The company was also already doing windshield replacement, which gave it a very good starting point when it came to calibration.

“We analyze the electronic data before, during and after the repair to know exactly what needs to be replaced and calibrated,” he explains. Then, step by step, the equipment shows us the processes to be followed according to the manufacturers’ requirements. Every step is documented, even the results of our road tests, to ensure that all systems are in perfect working order before returning the vehicle to the customer.”

The formula developed by this workshop is based on the fact that all mechanical work is also carried out in-house. Calibration fees are charged at the mechanical rate, which is higher than the collision shop rate. A normal charge, according to Etheridge, since this operation requires state-of-the-art equipment and trained technicians.

“Yes, calibration is a profit center,” says Etheridge. “It’s a nice addition to our services, because we also repair faster. Shops that don’t do it should start doing it, as we can see that more and more vehicles are equipped with ADAS systems that need to be taken care of.”

Paid at fair value

Michel Julien, Founder of MJConsultech, understood the importance of integrating ADAS calibrations by collision shops when he created the ADAP (Alliance Digitale Automobile Professionnelle) certification. By setting up a specific training program for calibrations, he has brought together a group of certified collision experts who have successfully completed the training courses and validated their expertise.

Aware of the investment required to achieve this objective, Julien established a calibration fee schedule that takes into account all the expenses incurred by the workshops. Shared with the main insurers, the grid is designed to be transparent and to ensure that collision shops are remunerated commensurate with their expertise.

“Shops that have obtained certification under our program are remunerated at the right price, since the insurers who turn to them understand the value and financial commitment required for good practice,” explains Julien. “However, it’s clear that a minimum number of calibrations is required to make the operation profitable. The more shops do, the more profitable it is for them. On the other hand, with our technical support and constant updates to our training platform, insurers who turn to ADAP members know that they’ll be guiding their customers to workshops that know what they’re doing, and are able to carry out ADAS calibrations to the highest standards.”

Warning

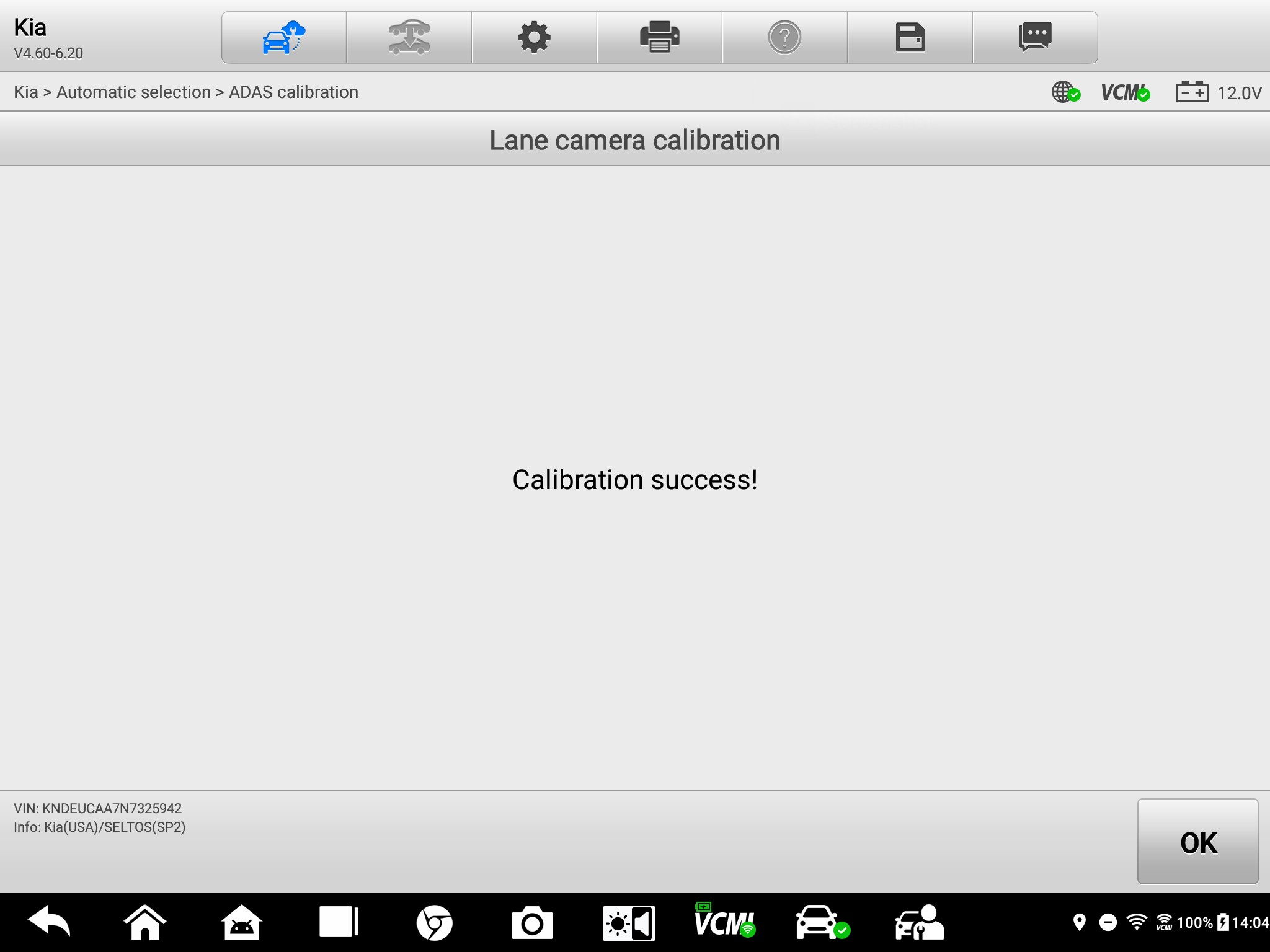

Michel Julien informs our readers that some calibration equipment on the market presents a major flaw: despite the monitoring of all calibration steps, no real adjustments are made to the cameras, radars and other sensors of ADAS systems. A report of successful operation can even be produced when no safety system has actually been calibrated or adjusted.

In his opinion, the only way to be sure that a calibration has been carried out on a vehicle is to obtain confirmation from the vehicle via the scanner. This is the last window to appear following calibration, as shown in the illustration below.