For those collision repair service providers who wish to verify and perform wheel alignments on the vehicles they service, the various equipment options that follow may very well correspond to their needs.

Alignment equipment distributors agree that before proceeding with this final adjustment prior to delivering the vehicle to the customer, however minor the collision, it’s important to confirm that the structural integrity of the vehicle has not been affected. “Before checking the alignment, it is important to ascertain if there is any other damage that could affect the steering, suspension or the chassis itself,” explains Éric Lefebvre of Auto Traction.

He refers us to the John Beam representative, Pierre Courchesne, who recommends the V3300 mobile unit or its fixed version, the V2380, “These machines allow us to validate the vehicle’s suspension geometry and chassis alignment according to the vehicle manufacturer’s specifications,” he explains. “If the collision repair shop already has a chassis straightening table, we also offer a surface mounted unit, consisting of trays that fit under each wheel. However, the work height is not ideal. Whichever solution is selected, the investment in alignment equipment pays off. The collision repair shop controls its costs and can better manage the time spent repairing vehicles.”

Detailed portrait

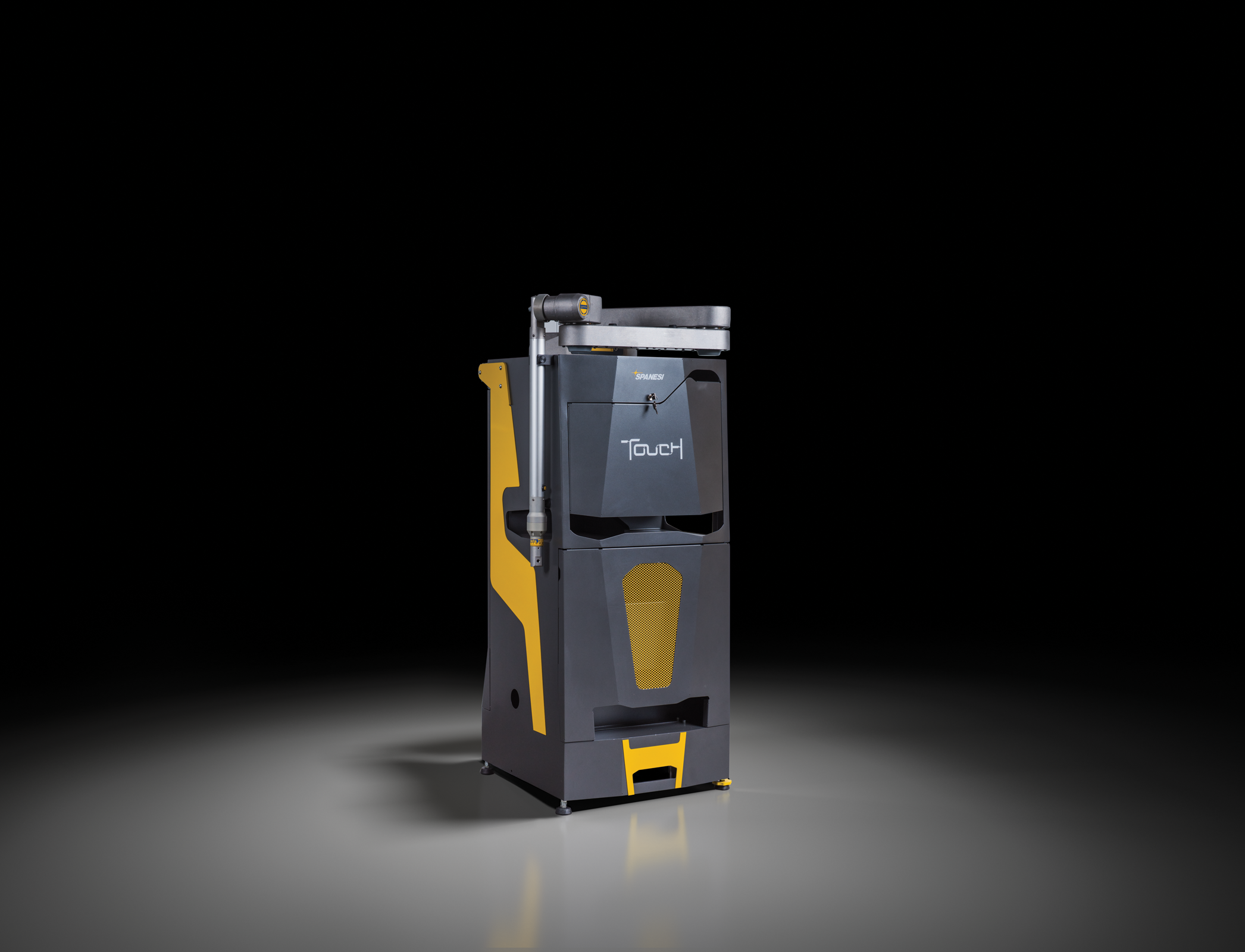

As for equipment supplier Spanesi of Americas, the solution lies in its Touch Wheels technology. “With this technology, the shop can make a more detailed diagnosis of the alignment of the wheels,” explains Karl Kirschenman, Director of Communications and Technology at Spanesi. “The electronic measurement system will capture and validate all of the vehicle’s measurements before proceeding with the alignment. In fact, every vehicle that enters the shop should be measured in this way to ensure that its chassis complies with the vehicle manufacturer’s specifications.”

As Karl Kirschenman points out, the complexity of modern vehicles, which are often equipped with advanced driver assistance systems (ADAS), these vehicles require that a rigorous and documented diagnosis be performed prior to commencing repairs. The Touch Wheels system can therefore identify not only the quality of the alignment, but the condition of the chassis, suspension, and other mechanical parts.

Subsequently, the alignment must be performed by qualified technicians with access to precision equipment.

When talking about precision alignment equipment, one cannot leave out Hunter Engineering. In this instance, we are talking about the Hunter HawkEye Elite. Although the equipment was launched a few years ago, it is constantly being updated and improved. For example, the new QuickGrip wheel adapters are twice as light as the previous version, take up less space, and are designed to avoid damaging the wheels.

Ease of use

Combined with the Premium RX vehicle lift, the HawkEye Elite captures all of the readings and delivers measurements in 70 seconds. This integrated, comprehensive alignment procedure, combined with Hunter’s WinAlign system, displays simple instructions directly on the technician’s screen. Drawing on a database of 220 million North American vehicles, the software guides the technician step-by-step.

For his part, Donald Thibault, Sales Representative for equipment distributor ISN Canada, the mobile, wireless Rotary R1065 is a popular solution for our market. “This easy-to-use equipment is based on interaction with a touchscreen tablet,” explains the equipment specialist. “It is ideal for workshops that do not have much space.”

Adjustment instructions are communicated in real-time on the tablet and the result of the measurements and adjustments required can be shared electronically with the customer. As the unit is mobile, it can be moved from one repair bay to another.

Rotary has also just launched a fixed version of this equipment, the R1090 alignment machine.

Compact, and easy to operate, it represents an affordable solution for a collision repair shop that wishes to acquire the ability to perform wheel alignments in-house. Equipped with fixed cameras, wheel adapters and remote controlled sensors, it can be operated via a console or digital tablet.