UV technology has been introduced to shops in recent years, bringing great changes for those who have adopted it.

Two-component urethane primers have been used for years in vehicle repair. They are designed to fill minor defects and provide a smooth, even surface for the next step of painting the damaged panels.

Conventional urethane primers play an important role in the total cycle time of a repair. Once applied, there are two options available to dry them before they can be sanded. The first is to accelerate the drying process using heat or infrared to increase productivity. Depending on the number of coats and the thickness of the film, drying can take from fifteen to thirty minutes on average depending on the process.

The second is to let the product dry by itself, slowing down the cycle time considerably. In this case, the waiting time can be a few hours or up to the next day, depending on the conditions, the number of coats and the film thickness. If you sand without sufficient time, there is a good chance that you will have problems with shimming and other defects in the final appearance of the paint finish.

The benefits of UV

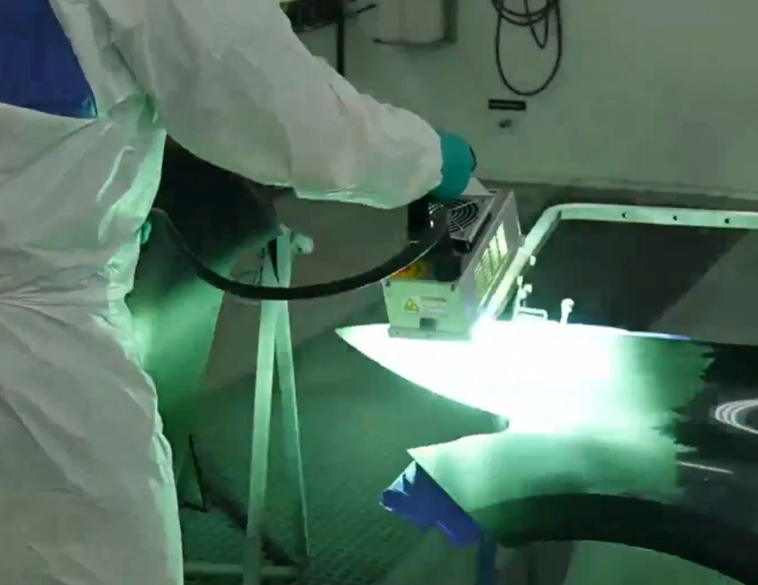

UV technology is different. The primer contains photoinhibitors in the form of small bubbles that act as a hardener. There is no mixing of products required. Once applied, the primer is exposed to UV light. The bubbles will dissolve, releasing the hardener and causing it to dry.

One of the main advantages is the fast drying speed. In fact, depending on the technology used by the manufacturers and the UV radiation used, the primer dries between 30 seconds and a few minutes. This provides the opportunity to offer a one-day “fast lane” repair service for minor repairs.

There are also several other advantages. First of all, the curing of the primer is complete if the application and drying parameters are respected. No shimming will be possible once painting operations are completed.

Less waste

There is also an economy of material. It is difficult to estimate with great accuracy the amount of primer required for a repair. With a urethane primer, any remaining material should be discarded, as it will eventually harden. However, any remaining UV primer can be returned to its container, as it will only dry when exposed to UV light.

Wearing the proper protective equipment is paramount. Respiratory protective equipment is required. Exposure to UV radiation is hazardous to the skin and eyes. Protective suit and gloves are required to protect the skin. A visor with an adequate protection factor is also required.

Technologies are evolving and you just have to take advantage of it to improve your productivity.

Normand Cormier is the North American Classroom Training Manager for Axalta Coating Systems [email protected].