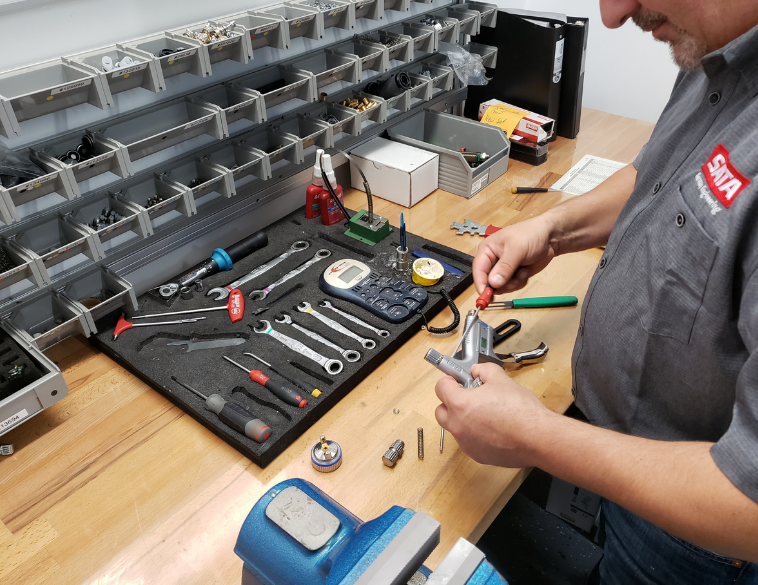

Proper spray gun maintenance makes a huge difference.

It can be easy for us to blame the materials or the apparatus we’re using when we don’t get the required result from a job we’re performing. The automotive refinish industry is no exception.

What we’ve found is that 99% of problems relating to gun and spraying performance are attributed to not following paint manufacturer recommendations and pressure mixing for the right viscosity, followed closely by spray gun maintenance.

Eliminating potential problems

If you’re cleaning a spray gun correctly, the job can be performed in less than 3-4 minutes with under an ounce of solvent. If you’re diligent in cleaning the gun properly after each use, it eliminates virtually all problems associated with spraying.

Where the issue often lies, is when a gun is dipped in a solution to clean it. What happens then is that the solution covers everything and makes its way into the air passages of the gun. When a solution goes through the air hole, it can destroy the seal on the air meter, which renders the gauge inoperable, by allowing the solution to contaminate the battery which operates it. When this happens, the gauge needs to be replaced in order for the gun to function correctly.

Furthermore, there’s a plastic tube in the air passage that can be easily damaged by using solvent solutions. Often these solutions can be so dirty, small chunks of paint can get stuck in the air passage, creating an air pressure issue. The seals in the air passages, if exposed to solvents tend to harden and crack, causing air leakage in the gun. When air leaks from the piston, it ruins the air micrometer.

Also, if the air cap is removed and the seal for it has been soaked in solvent, when you install the cap again and tighten it, the softened seal doesn’t allow the cap to seat properly, causing leakage.

When cleaning the air passages, tiny brushes are required to do the job properly. These small passages are precisely formed, and the brushes are designed not to damage the inside of the gun. In some cases, we’ve seen situations where a drill bit is used to try and get paint out of the hole. Using the bit alters the shape of the hole and changes the way the air moves as well as the spray pattern, destroying the functionality of the gun.

When this happens, a painter will complain that the gun is useless, when in reality it has nothing to do with the tool itself, but the lack of proper maintenance.

Proper maintenance equals longevity

If you follow the required maintenance schedule on a spray gun, it can last for 20-25 years and there are painters and collision centres in our industry that are still using the same guns after a quarter century because they know how to maintain them.

Not only does poor gun maintenance reduce productivity and the quality of the work performed in the spray booth, it also impacts the shop due to the amount of extra paint required when working with a faulty gun.

For example, if the cost per ounce of paint is $4 and I’m using 10 ounces more on average per repair because my gun is not maintained properly, that quickly impacts the bottom line.

Over time, like any piece of equipment, lack of maintenance causes capability to diminish. You’ll find the gun performs increasingly poorly and the negative impacts associated with that compound. As a result, you end up with lower quality work, an increase in cycle time, plus more costly consumption of paint and materials, until eventually that gun needs to be rebuilt or replaced. And all of it could have been avoided if proper gun maintenance procedures were followed from the beginning.

John Turner is General Manager for SATA Canada. You can reach him at [email protected]