Few collision shops have the equipment to calibrate ADAS sensors and cameras, but things are about to change.

Major collision repair networks are not unaware of this important issue. Not being able to make these adjustments in-house means having to outsource them to others, namely dealerships. The shop then exposes itself to delays and invoicing beyond its control.

But before jumping into this new technological adventure, which involves major investments, several questions arise. Do the volumes justify the investment? Or which technologies to adopt?

Yves Robichaud, Regional Director for Quebec at CARSTAR, asks himself these questions.

“Yes, we have to position our collision shops to do so. We are currently discussing this issue with our partners to determine the best equipment and the most effective training programs. The first question is: do you have the space to accommodate this equipment within the required dimensions?”

Space to accommodate equipment

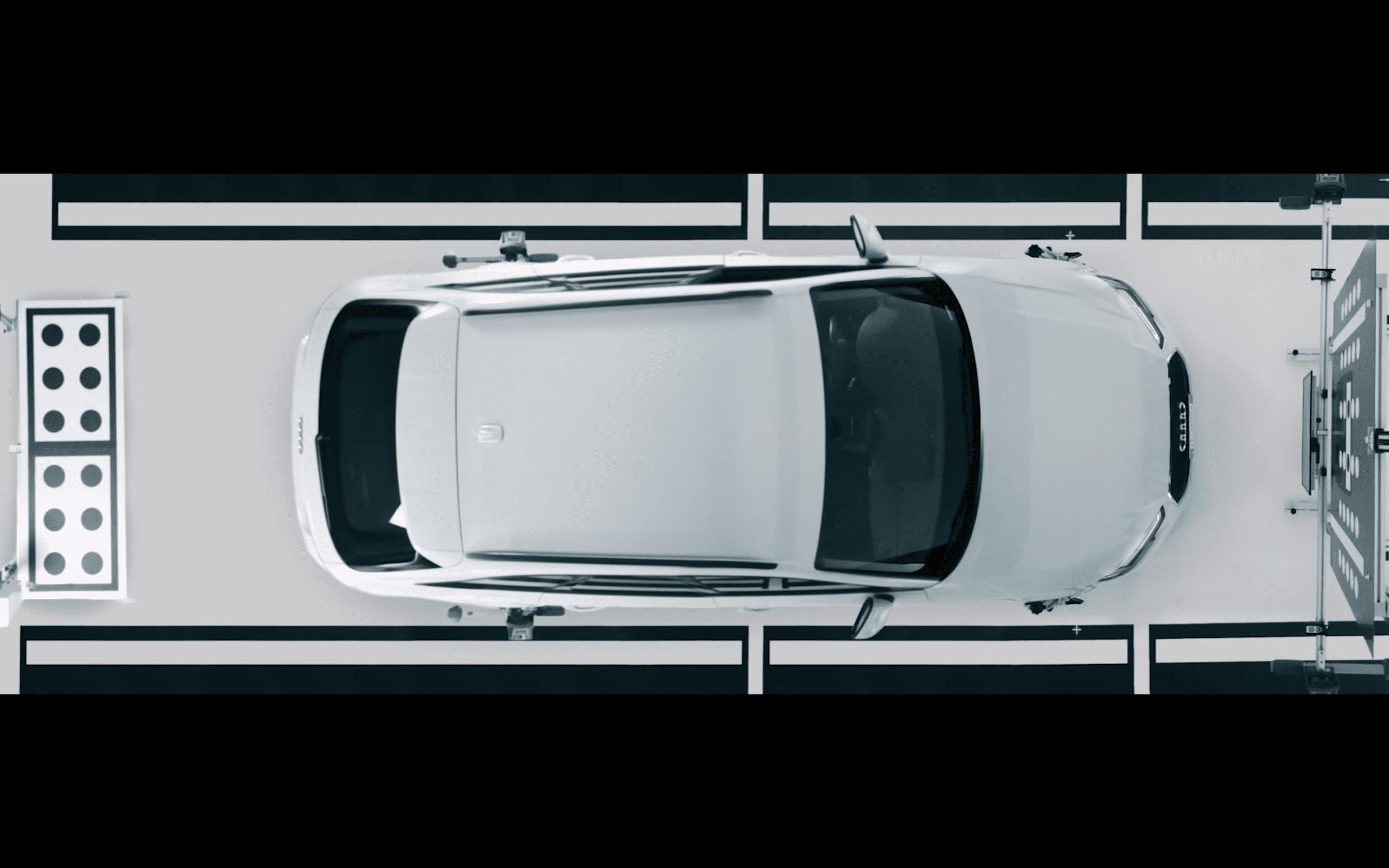

Depending on the supplier, a room ranging from 20 x 40 ft to 40 x 70 ft is needed to do the calibration. Few workshops have the luxury of having this space.

The current industry figure is that one out of every 30 body shops, across all banners, has such a facility in place.

“I agree with that estimate,” says Robichaud. “We are currently looking at which shops in our network would be able to make this investment and if it isn’t possible, to share the service with other shops.”

This is already happening in the United States, where centres solely dedicated to the calibration of automotive sensors and cameras offer this service on a subcontract basis.

As Robichaud mentioned, the question of space is crucial.

“To have the ideal room, you almost have to consider a lab space,” says Nick D’Amico, Technical Sales Consultant at Filco Equipment and Services. “At least 20 feet wide by 40 feet long, with white or plain walls and no extraneous lighting from outside, all resting on a level floor.”

“Then we’re talking about an investment of about $30,000 for equipment. But properly equipped and trained, a body shop will be able to work on ADAS systems on 90 to 95 percent of the vehicles it is assigned.”

A specialized technician

D’Amico goes further to stress the importance of hiring or training a specialist in the shop whose main duties will be to perform electronic diagnostics and calibrations of ADAS systems.

In terms of calibration equipment, Filco offers the system from European supplier TEXA. An integrated solution that allows the workshop to become autonomous.

As D’Amico says, the time has come to invest in these technologies. Shops that provide windshield replacement service first.

“I understand that the shops that are moving in this direction are few and far between right now,” he says. “But it’s the way of the future. And a well-structured shop with an estimator who can detail the time it takes to calibrate and schedule is going to pay for its investment within a year.”

Filco Equipment and Services has its own training center where it invites body shop managers to see TEXA equipment in action.

Simpler

“It’s a technology that, at first glance, is scary,” says Jean Chamberland, ISN Group Representative in Boucherville, Quebec. “But body shops have never shied away from a challenge. What’s more, the new sensor and camera calibration equipment linked to ADAS systems are much easier to use.”

“As with any learning curve, the first few calibrations take more time, but with practice, a good technician will quickly get up to speed.”

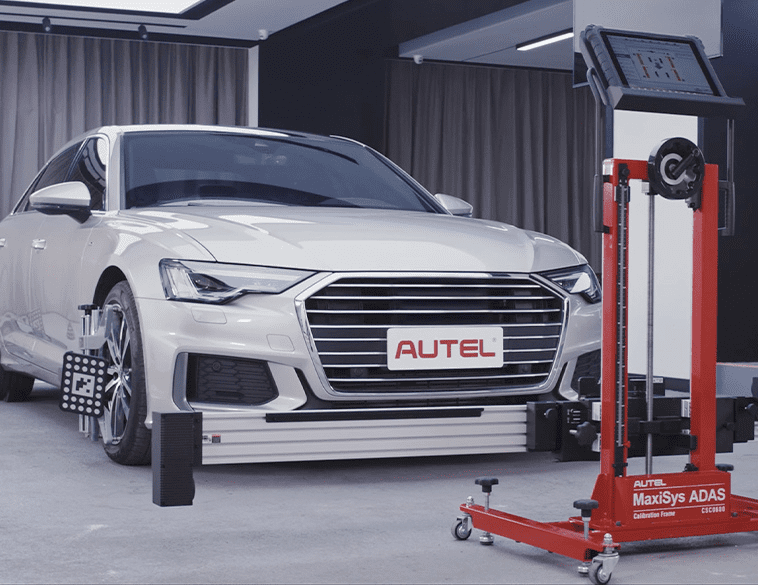

At Groupe ISN, AUTEL MaxiSys ADAS calibration equipment is offered to body shops.

It is a versatile package that adjusts sensors related to adaptive cruise control, 360-degree vision, blind spot and lane departure detectors, obstacle detection, night vision and rear impact warning.

The fixed or mobile mount and targets range from basic calibrations to the most complex operations.

“The advantage of AUTEL equipment is that it will show you, step by step, how to complete the process in the right way,” says Chamberland. “Everything from choosing the right target panels to the measurements that need to be made to the mats that need to be positioned on the floor for lateral calibrations is indicated.”

He also mentions that these packages are upgradeable and complementary accessories are available as soon as a vehicle model comes on the market with new generation ADAS elements.

Scissor lift

Chamberland notes that the shop should have a floor-mounted scissor lift in its electronic diagnostics and calibration bay. The pole jack can be a hindrance to operations.

Marc Robert, President of Auto Traction, offers the EZ-ADAS platform under the Car-O-Liner brand. But he says he invites body shops to be patient as a new version is currently in the works.

“The EZ-ADAS solution was already exceptional. But with an updated database, among other improvements, users will have a simpler and more complete system in hand.”

Robert says there’s no doubt that body shops need to commit to working on advanced driver assistance systems. “First and foremost, it’s a series of processes to follow, on which the safety of our customers directly depends.”