The field of collision repair has evolved tremendously in the course of the last few years.

The equipment used today is much more efficient than before. This technological progress has enabled us to achieve a repair whose quality is comparable to the manufacturers.

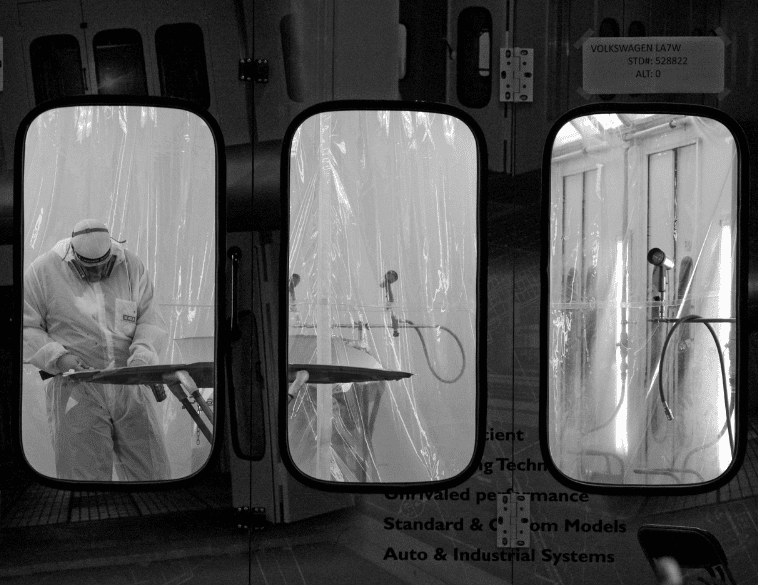

MIG welders, spot welders, straightening benches, sophisticated tools for removing dents from metal or aluminium, paint chambers, spray guns, anti-static tools, to name a few, allow for a safe and professional repair.

Training

However, all this great equipment is nothing without the expertise of trained and qualified technicians. A robot can assemble a new vehicle with flying colours. However, when it comes to changing a side panel or a rocker panel and then painting the vehicle with a colour match, there is nothing like a skilled and detail-oriented workforce to do the job right.

Insurance companies now require approved shops to have this equipment in order to ensure the safety of their customers. Sloppy or poorly done work can lead to serious consequences and even endanger the lives of vehicle occupants.

Obviously, there are costs associated with compliance, particularly in terms of equipment and staff training. Dealers and collision repair shops have all updated their equipment to provide their customers with unparalleled service.

Whether you join the parade or watch it go by, that’s the choice collision repair shops have to make.

Denis Chevrier is a senior technician and trainer at Sherwin-Williams. [email protected]