A Ford SUV has problems blowing cold air.

Recently, we came upon a very interesting case. There was a 2017 Ford Escape with a customer complaint of the A/C not blowing cold air. Previously the vehicle had the A/C compressor replaced due to the clutch failing previously.

Engaged, but not cool

When we looked at the vehicle the clutch was engaged but the system would not cool. On these vehicles, the A/C system uses a variable displacement compressor and 1234YF refrigerant. Other than those two distinctions the system is a conventional expansion valve type system.

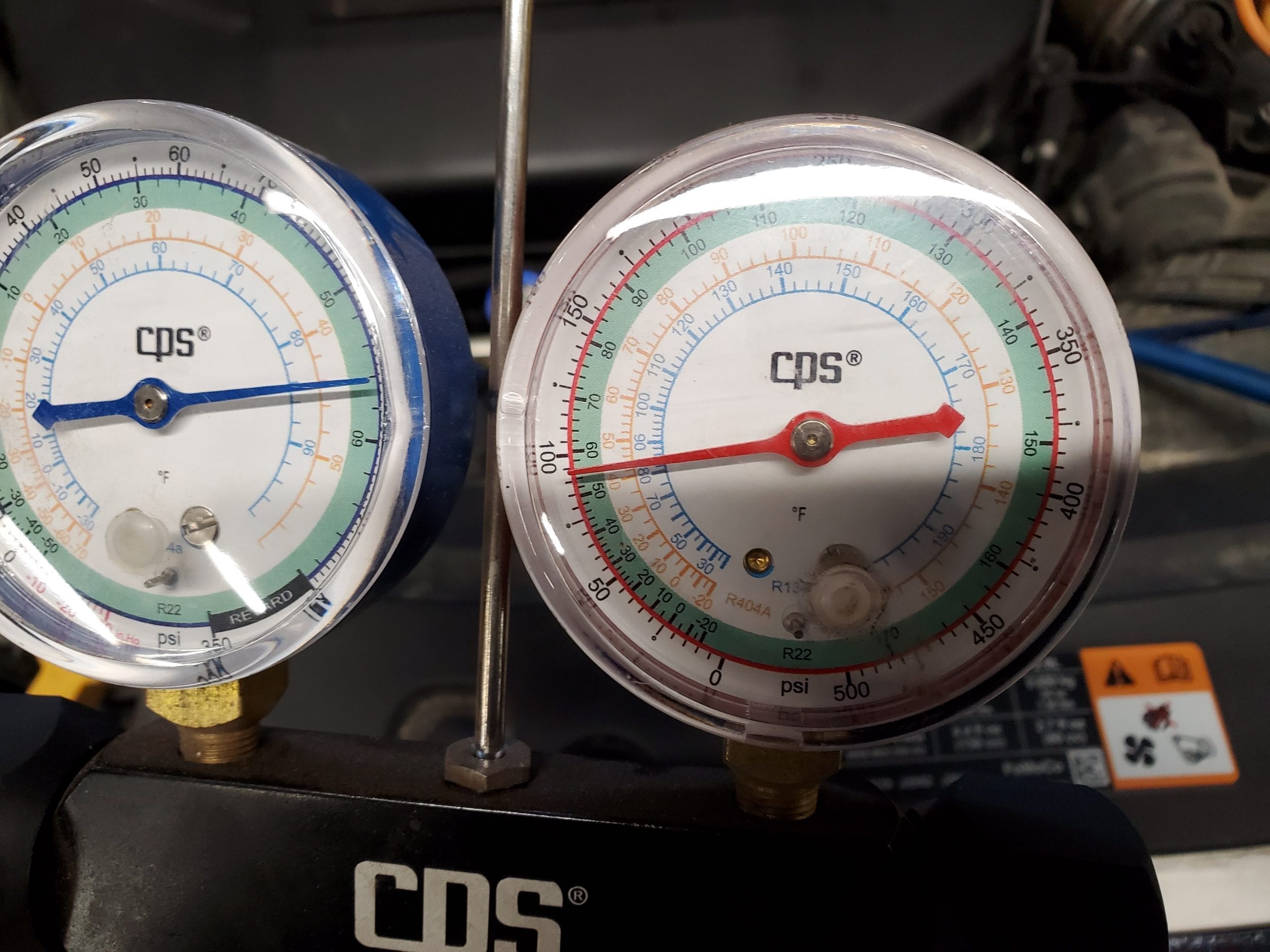

The first step was straightforward—we hooked up the pressure gauges to see what was going on and took a quick look at the scan data for codes and clues. With the gauges hooked up and the engine running, plus the A/C system turned to MAX cold the gauges (Fig 2) showed that the system was not low on refrigerant but there was no pressure change between the high and low-pressure sides with the compressor running.

Pressure changes

Looking at how the system works and delving into a little bit of AC theory (Fig 3) we know that there are two pressure changes that must take place in the system for it to produce cold air. The first is a pressure increase which takes place in the compressor and the second is a pressure decrease at the TXV (thermostatic expansion valve). In our case, the pressure is registering at 85 psi on both sides of the system. This can happen in one of two ways, either there is no refrigerant being circulated or the TXV is wide open and there is no restriction in the system.

We then checked the scan data to see if the compressor was being commanded on. When we looked at the data (fig 4), the PCM was commanding the compressor to operate at a high flow rate. The PCM is commanding the compressor to an 85 % duty cycle which is close to maximum flow. On this system, a high duty cycle indicates higher flow rate from the compressor. Clearly the PCM wanted high refrigerant flow. It looked like the PCM was commanding the correct response but the underlying question of whether this is a compressor or TXV problem was still not answered.

No change in pressure

Theoretically, if the TXV is stuck open there would be no restriction in the system to create a pressure change, also if there was no refrigerant flow there would be no pressure changes. So, which one was it? First, if there is sufficient flow (Maximum is being commanded) through the TXV even if the valve is not closing, we should have seen a slight change in pressure or temperature across the TXV. We saw no such change in pressure. This would seem to indicate that we have no or low flow which takes us back to the compressor. The question now seemed to be whether the compressor was being driven properly by the PCM. When we checked the scan data the PCM indicated that it is applying an 85% duty cycle and about 850 milliampere (mA) of current. We used a low amps probe and scope and measured the actual current to the compressor.

Faulty compressor

We measured 875 mA of current applied to the control solenoid in the compressor. This should have been enough current to command the compressor to the maximum flow rate which should have resulted in some change in pressure. Since we saw no pressure change at all we concluded that the compressor was faulty and should be replaced.

In this case, understanding the system and its operation led to a quick diagnosis.