NAFA AFLEET webinar delved into a whole host of parameters regarding fleet EV operation.

On August 15, as part of NAFA’s EV Tools of the Trade webinar series, a session focused on Alternative Fuel life-cycle Environmental and Economic Transportation (AFLEET), was presented by Andy Burnham, Principal Environmental Scientist, Argonne National Laboratory, and Tyler Hermann, Coordinator, Louisiana Clean Fuels.

This session aimed to give attendees a chance to understand how the AFLEET tool can help fleet managers compare the cost of ownership, fuel consumption, plus air and pollutant emissions output of conventional vehicles versus their electric counterparts.

Given that vehicle emissions regulations are changing all the time, and fleets are looking for answers to this while seeking to minimize operational and ownership costs of their assets, the ability to use a tool like this effectively becomes of paramount consideration.

Misconception

Andy Burnham said that a big misconception regarding electric vehicles concerns operating costs. “Oftentimes, you hear that all EVs have zero maintenance costs or similar hyperbolic responses to that effect. And the reality is no. They do have many of the same components even though an EV’s driveline might contain fewer moving parts.”

A big one of course is tires. An EV is typically heavier than its gasoline/diesel counterpart and the instant torque from the electric motors puts added force on the tires. As a result, tires often tend to wear faster, so this is something fleets need to consider. Another is braking, specifically the lifecycle of braking components. A lot of this depends on the driver of the vehicle, as well as road and climate conditions such as slush and salt in the winter, plus in the case of EVs, whether the driver is really utilizing the vehicle’s regenerative braking system.

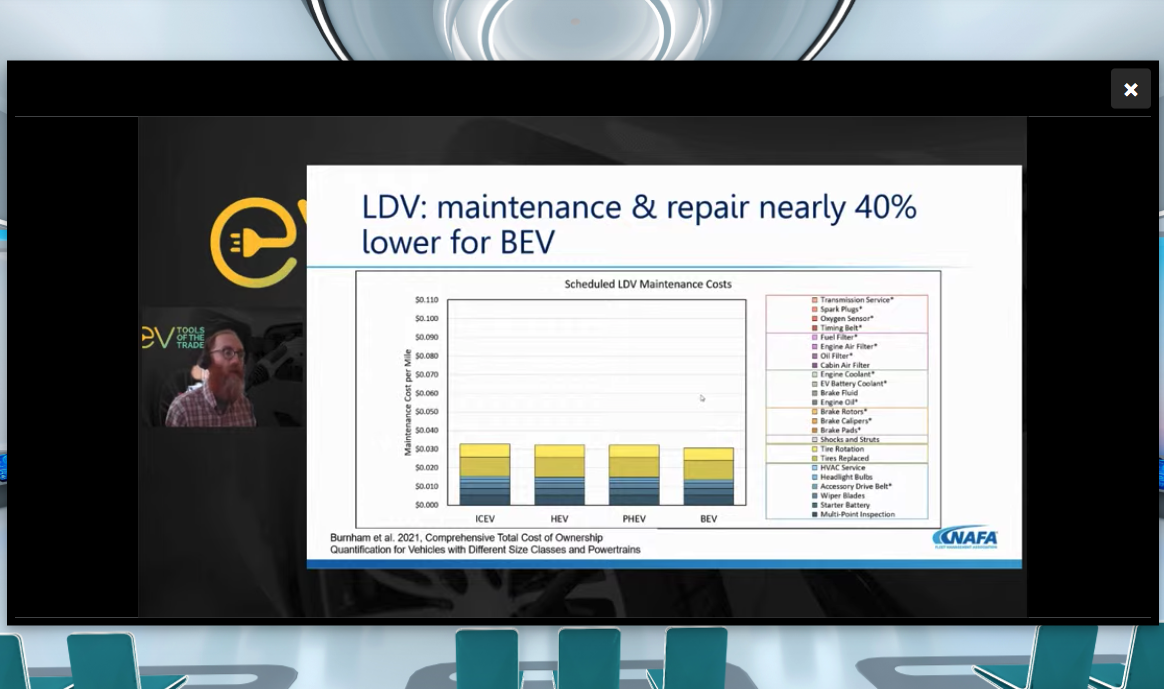

According to Burnham, once you get behind the cost of the vehicle itself, the savings can really be found in regular maintenance, for example, the savings on belts, filters, sparkplugs, and fluid changes. “We see about a 40% reduction in maintenance and repairs for EVs,” though he stressed this was for pure battery electrics. For hybrid vehicles, Burnham noted that while the same approach didn’t really apply, real-world data did demonstrate that significant savings can also be had on both regular and plug-in hybrid vehicles compared with their conventional counterparts. Therefore, being able to determine savings like this using a tool like AFLEET can prove to be a major game-changer for fleet operators; especially in today’s environment of rising inflation, operating costs, and often, limited budgets.

Electricity costs

Burnham did caution, however, that when using analytics to compare operating and maintenance costs between different vehicles, it was important to consider data that was powertrain specific and that which wasn’t. One issue currently facing electric vehicles is the cost of charging them, of which data from AFLEET is not publicly available at present. Given how electricity costs vary significantly across North America, this can have a major impact, as well as the type of chargers you use, how frequently you use them, and the times of day or night when you actually charge your vehicles. “What we see is that if you are charging during peak times where demand charges are high and you are using multiple high-output chargers that are above 50 kilowatts, electricity becomes very expensive, very quickly.”

To provide fleets with a better understanding of overall EV operating costs, Burnham and his team worked on both a spreadsheet and an online tool designed to help managers analyze what potential electricity charges would be for their vehicles, depending on the utility they are working with, the rate and time of use.

“Does your region have an EV rate?” Burnham asked. “Also, how are you managing your charging strategy? Are you basically setting it up where you’re charging at a certain time period?” He explained that avoiding peak charging periods can provide bigger windows of opportunity, particularly if fleets can reduce their power uptake due to having longer windows in which to recharge their vehicles. Such information, available via an online tool, would prove highly invaluable to fleets and it’s something the Argone National Laboratory is currently looking to release in the future.

Another consideration is working with your local utility provider. If they have an understanding of what your requirements will be in terms of the number and type of vehicles and the frequency and strategy for charging, they can help fleets build out a suitable charging infrastructure that meets requirements without resulting in major cost overruns such as having to rip-up and replace chargers multiple times because they are not suitable to requirements.

Tyler Hermann, Coordinator for Louisiana Clean Fuels, which is part of the Clean Cities Coalition, a U.S. Department of Energy initiative that’s designed to build partnerships and find practical solutions for EV adoption in cities across the country, talked about ways in which fleets can reduce their carbon footprint, while at the same time actively taking advantage of the various initiatives and grants available to assist in transitioning to lower emissions vehicles.

Government grants

Moving into specifics, Hermann talked about how tools like AFLEET can not only help fleets identify where emissions reductions can be made within their current assets, but if they are able to demonstrate real reductions, this can also provide them with a better chance of obtaining government grants related to EV acquisition and use. Hermann explained that based on his own experiences, he’s found AFLEET to be a well-regarded and robust tool in helping fleets determine vehicle emissions and the cost of ownership. Hermann explained that Louisiana Clean Fuels was able to extrapolate all the data it had on reduction in Oxides of Nitrogen (NOx) via AFLEET and then create a simple, easy-to-use document that allows fleets to input old vehicle data and new vehicle data. The result enables fleets to compare emissions and costs of one type of vehicle fleet against another and as a result, make more informed decisions when it comes to selecting vehicles that will reduce that fleet’s overall emissions while at the same time helping it effectively manage operating costs.

For those fleets that actively track data via telematics, such as fuel pricing and maintenance costs, Hermann explained that a tool like AFLEET can provide even more accurate information. By having the ability to also input available rebates, such as those for low emissions vehicles or infrastructure programs, in addition to comparable fuel and maintenance requirements for different types of vehicles, fleet managers can have a complete, holistic view of what those vehicles will actually cost to operate, instead of just relying on piecemeal information such as fuel and maintenance data, which can often distort real-world TCO.