The all-new 2021 Nissan Rogue is breaking new ground as the company’s first global model built using a “closed-loop” recycling system for aluminum parts.

The system helps reduce CO2 emissions compared with using parts made with primary alloys from raw materials. It also promotes the use of materials that don’t rely on newly mined resources, as well as the reduction of waste from factories.

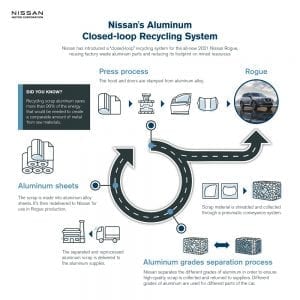

The hood and doors of the 2021 Rogue are stamped from aluminum alloy, a material that reduces vehicle weight and helps improve fuel efficiency and power performance. The model is built in Kyushu, Japan, and Smyrna, Tennessee.

To support the process, Nissan has collaborated with Kobe Steel, Ltd. and UACJ Corp. in Japan, and with Arconic Corp. and Novelis Inc. in the U.S.

Recycling and reusing

At the core of the closed-loop recycling system is a large pneumatic conveyance system. As hoods and doors are stamped into shape, scrap material is shredded and extracted, keeping aluminum grades separate.

The separation ensures that Nissan can return high-quality scrap to suppliers. The suppliers turn the separated and reprocessed aluminum scrap into aluminum alloy sheets and redeliver them to Nissan for use in production.

According to the U.S.-based Aluminum Association, recycling scrap aluminum saves more than 90% of the energy needed to create a comparable amount from raw materials. The organization estimates that nearly 75% of all aluminum made is still in use.

Nissan Green Program 2022

Under the Nissan Green Program 2022, Nissan aims to replace 30% of the raw materials used in cars built in 2022 with materials that don’t rely on newly mined resources. To achieve this, the company will use recycled materials and develop biomaterials, carry out recycling activities both at suppliers and in-house, and seek to reduce the weight of car bodies.

Nissan will continue to promote efficient and sustainable use of resources, including the use of renewable resources and recyclable materials.