At the 2023 SEMA Show in Las Vegas, Autosphere had the opportunity to visit with the team from 3M Automotive Aftermarket.

According to Jason Scharton, Senior Manager, Global Expertise Delivery, a key focus for 3M has been on consistently improving the collision repair process through a combination of equipment, solutions and training. I

n October, 3M officially opened its Skills Development Center (SDC) in St. Paul, Minn. According to Scharton, the SDC represents a benchmark of instructor-led, collision repair training that allows repair centres to adapt to industry challenges and tackle ongoing labour shortages. Multi-day technician training courses are a fundamental part of the SDC, all taught by seasoned collision repair experts, many of whom started their careers on the shop floor. Scharton acknowledged that while products, including consumables, have long been a core part of 3M’s strategy related to collision repair and the aftermarket, at the SEMA Show, the emphasis was on tackling three major challenges facing many collision repair centres, namely labour shortages, skills requirements, and profitability.

This is why there’s been a big push on repairing versus replacing parts wherever possible since it ultimately saves time and boosts profitability for the shop. The challenge is finding the right technicians and properly upskilling them to the work.

“There is [currently] a tremendous number of sales happening in storage,” said Scharton, referring to the fact that many collision repairs are currently delayed because parts are back-ordered. While some collision repair centres are getting around this issue by charging storage fees, when those are taken away, many are losing money. “They don’t have enough work going through to pay for their fixed costs,” Scharton explained.

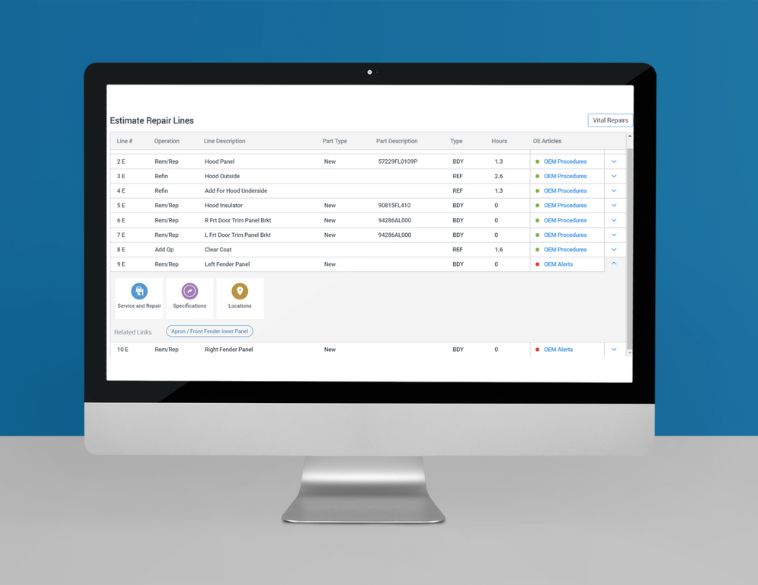

That’s why 3M has been laser-focused on finding solutions to help tackle this problem. One way is by simplifying the repair process and offering digitized solutions that march in lockstep with the growing electronic complexity and connectivity of today’s vehicles. 3M’s RepairStack Performance Solutions, launched in 2022 exemplifies this approach. A hardware and software system designed for inventory management, integrated invoicing, and performance analytics, it enables collision centres to actively track material usage and ensure replacements are readily available, as well as fast, accurate and transparent business performance insights, as well as efficient blueprinting and billing. Additionally, RepairStack is designed to go beyond that, allowing collision centres to connect with OEMs for certified repair procedures, ensuring the right tools and materials are utilized for the right repair, and helping minimize inefficiencies.

Another big announcement at the SEMA Show was 3M PPS Series 2.0 Vented Spray Cups. Designed to provide automotive painters with a new level of simplicity and convenience, these were introduced following feedback among collision shops that sought vented cups to ensure greater flexibility when spraying in the booth. Combined with 3M’s Performance Spray Gun, the new cups attach via the same linered system used for the 3M PPS Series 2.0 Cups, enabling painters to quickly switch from one cup format to the other. This enables maximum flexibility, allowing the painter to apply everything from light primers to heavy base coats, spot spraying and even bulk spraying while minimizing downtime.