In the next five years, the collision repair industry could see more change than it has in the last 50.

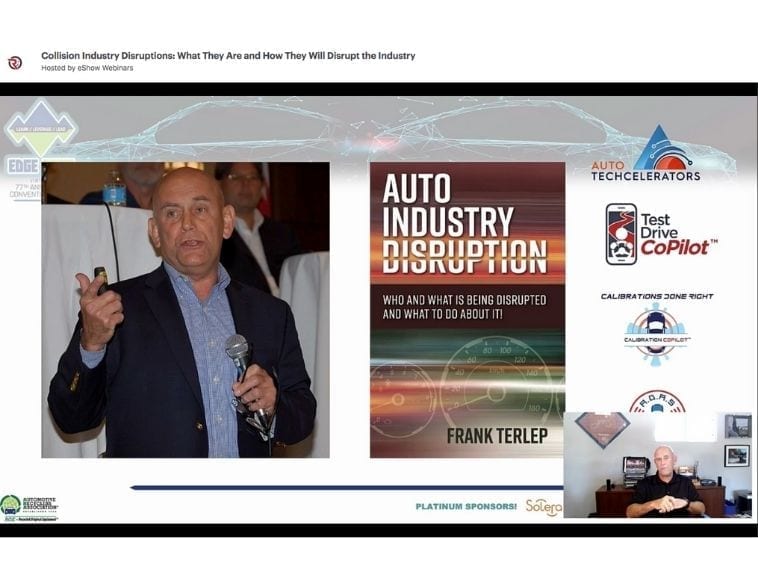

As Part of EDGE 2020, the ARA’s 77th Annual Convention & Expo (in virtual format this year) due to the COVID-19 pandemic, Frank Terlep hosted a session entitled Collision Industry Disruptions: What They Are and How They Will Disrupt the Industry.

Terlep, who has been involved with the automotive industry for more than four decades and recognized as a pioneer in implementing information technology solutions, including his latest venture which he co-founded, Auto Techcelerators, dove into a variety of new topics that are front and centre for the collision repair and automotive industry.

Disruptor or disrupted?

The question of course, when it comes to disruption in the collision industry is whether you’re going to be a disruptor, or be disrupted?

Terlep focused on six different factors that have or are expected to change the way the collision industry operates and with it, the way in which auto recyclers fit into the ecosystem.

These six items are:

- The impact of COVID-19 on fast-tracking insurance industry technologies

- Vehicle electrification

- Connected cars and Big Data

- Artificial Intelligence

- How Virtual Reality and Augmented Reality will change the repair process

- The impact of these technologies on the auto recycling industry

Starting off with insurers, Terlep said that typically, in the past, insurers moved slowly when it came to implementing technology, however, the onset of COVID-19 has forced a drastic change in the way insurers and the claims process operates and many are now investing billions of dollars to introduce new technologies and create a contactless claims experience that is accurate and efficient.

Four technologies

Terlep noted that the top four technologies insurers are currently focusing their efforts on are Artificial Intelligence and Machine Learning; automation of processes, digital portals and cloud storage.

In some cases, by leveraging these technologies, insurers could see up to a 40 percent reduction in operating expenses.

The use of data analytics can help insurers to better understand and forecast consumer behaviour, while leveraging machine learning technology can help result in programs and solutions that are more accurate and relevant to the needs of their clients.

You can’t have a discussion regarding industry disruption today without talking about vehicle electrification.

Thanks to the well-publicized story of Tesla, battery electric vehicles have become the latest thing, with automakers, both legacy and start-ups trying to bring new models to market. Terlep said that globally, approximately 400 new models are expected to be introduced within the next five years, though a bigger question is how well they will be received in the market. Some of these new upstarts, such as Lucid Motors, claim a range of 500 miles on a single battery charge, so expectations are high.

Fewer parts

If electric vehicles do become mainstream, the nature of their design and construction will have a major impact on the service repair and collision industries due to the vastly fewer number of components they use, relative to traditional internal combustion engine (ICE) vehicles.

With fewer parts needed and different types of parts, repairing battery electric vehicles requires a different mindset and different processes for collision shops. In addition, with insurers adopting AI and Machine Learning, the First Notice of Loss (FNOL) is becoming increasingly digital meaning that not only can the claim be processed faster and more efficiently, but that the parts can be ordered prior to the vehicle even reaching the shop for repairs.

Additionally, technology such as Augmented Reality, which we’ve already seen from companies like Bosch, Mitchell and Spanesi, is allowing technicians to perform repairs more efficiently with direct access to technical support and pinpoint specific issues with greater speed and accuracy.

And as vehicles not only become more electrified, but also more connected, the ability to be able to harness and process that data becomes critical. Currently, the average connected car generates 25 gigabytes of data, a vast amount considering that we consume about 15 megabytes for web browsing and 869 megabytes for streaming videos on our smartphones or tablets.

Server driven systems

As vehicle technology evolves, Terlep noted that diagnostics processes within the collision and service shop will also change, with a move away from the traditional CAN BUS electronics architecture we’ve seen over the last two decades toward a secure gateway portal already being implemented by the likes of FCA and Nissan and ultimately, to a server-driven network like we currently see with office computing systems, where the server is driving all the data to the various modules and sensors throughout the vehicle.

Terlep noted that in the coming years, AI and Machine Learning is going to become an integral part of just about everything we do and while it will disrupt the way tasks and processes have been conducted, it also opens up many new opportunities and the ability for all stakeholders within the collision space to collaborate and communicate more effectively.