Continental Commercial Vehicles & Aftermarket has announced that it is offering a wide range of ATE Disc Brake Rotors that are designed to meet specific vehicle and customer applications.

The company explains in a release that it manufactures the rotors precisely using OEM materials of high quality in order to meet the specific requirements of the original disc brakes. To engineer the perfect solution for safe and comfortable braking, Continental leverages its more than 100 years of expertise and experience in brake systems when developing its rotors.

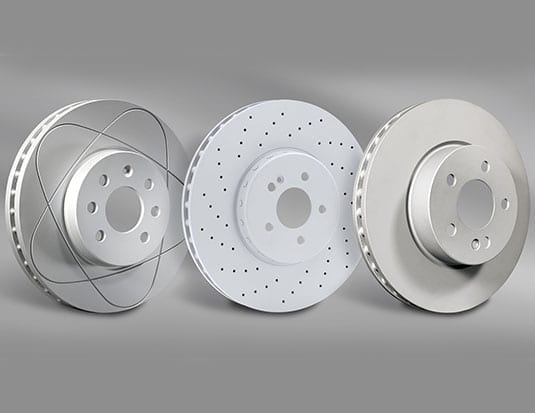

Continental adheres to high quality OEM requirements to develop precise products for its ATE Original Brake Rotors line that are built to exceed even ECE-R90 standards. According to the company, the products contain the latest technology as well as high quality materials and provide application coverage for a wide range of vehicle models. Each rotor is designed to match the OEM brake discs exactly as was installed in the vehicle be it smooth, drilled, high-carbon, one-piece, pinned or riveted, and with or without wheel bearings. Wide coverage is available especially for European makes and models with this product line.

Sporting a stylish, custom appearance, Continental’s ATE PowerDisc Brake Rotor line is built to handle braking safely in wet conditions and critical situations with innovative technology. In order to decrease fading and restrict scoring, the rotor features a patented multifunction groove machined into it that aids in eliminating dirt and gases. Continental notes that this ATE innovation enables technicians and customers to easily identify the amount of wear on the rotors with a glance, thus alerting them when the part needs to be replaced.

The ATE Single Pack Brake Rotor line has been built for providing excellent braking performance with ultra-low-noise and vibration, according to Continental. Matching the high-carbon content of the OE part, the rotors are created using OE material. The products are coated with special corrosion protection and have the capability of resisting high temperatures. Continental sells each rotor of this line individually. Coverage is available for a wide range of European make and models.

Dan Caciolo, Head of Product Management for Continental Independent Aftermarket Powertrain & Brake Systems, states, “Our ATE disc brake rotor programs offer the customer and technician multiple options all featuring high-quality materials, and most importantly over 100 years of OE brake system experience and know-how. We have everything needed to deliver optimal braking performance and the correct rotor for each individual application.”

VALLEYFIELD

VALLEYFIELD Full time

Full time