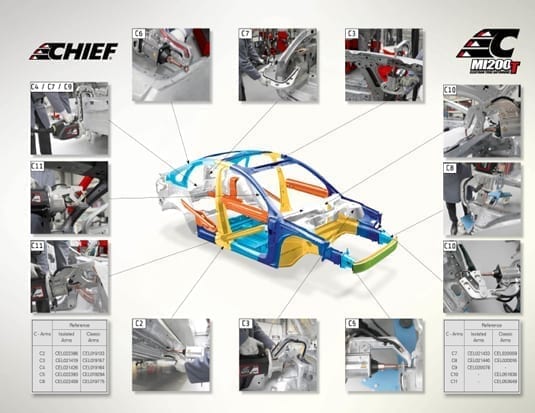

Chief now offers 19 different lightweight aluminum C-arms for its new MI200T squeeze-type resistance inverter spot welder.

The arms let technicians customize their spot welders to easily reach any location on a collision-damaged vehicle.

“Fixing collision damage on a vehicle is hard, physically demanding work. The right equipment can make the difference not only in the quality of the repair, but also in how sore the technician is at the end of the day,” said Mickey Swartz, Director of Global Product Management for Chief parent company Vehicle Service Group (VSG). “That’s why we built a number of ergonomic features into the MI200T spot welder, including lightweight transformer pliers, the industry’s longest welding cable, a standard overhead balancer with 360° Gyro attachment and a full line of lightweight C-arms.”

In addition to the C1 insulated arm that comes standard with every MI200T spot welder, shops can choose from 18 available C-arms, including insulated and classic (non-insulated) models. There’s an arm for every spot-welding application, from the C6 with a unique ball-shaped tip that fits on small, thin spots, to the C9 that has a reach of almost two feet (600mm) and a clearance of almost 10 inches (250mm). The C10 and C11 arms are available for applications that call for more of an X-arm style. Every MI200T C-arm also features liquid cooling to the tips.

In order to change arms, the operator pops off the cooling line, flips a lever and removes the arm. By reversing the steps, they can install a new arm and get back to welding in 10 seconds or less.

Every MI200T welder comes with the 360-degree Gyro attachment that lets technicians use the overhead balancer to support the welding gun while maintaining the ability to rotate it up to 360 degrees.

This allows the technician move the gun as needed, instead of trying to contort their body to work overhead or in other hard-to-reach spaces. The result makes for an exceptionally maneuverable welder when combined with Chief’s lightweight pliers, long cable and full range of C-arms.

The MI200T’s high-performance transformer pliers can produce up to 14,500 amps of welding current while drawing up to 40 percent less power than many cable pliers. This high-efficiency design means that the amperage service required for the MI200T is one of the lowest in the industry, typically requiring only a 40A service. In addition, the MI200T’s duty cycle is so high that the technician can operate the welder continuously without having to slow down to let the welder cool off.

Another key feature of the MI200T is Chief’s TrueAutoMode automatic welding system. TrueAutoMode detects the metal type and thickness, as well as the presence of adhesives and insulation, and then automatically adjusts and sets the welding parameters accordingly. It provides instant feedback to the technician about the weld result, while simultaneously logging the results into memory. At the end of a job, the technician can print out a report that includes information on the settings, messages and actual weld parameters of every weld, enabling the shop to document that its welds were made correctly.

To learn more about the Chief MI200T spot welder or any other Chief collision repair products, stop by booth #10116 at the SEMA Show, or click here.