How many mechanics do you really need?

A common question amongst fleet managers is, “Do I have the right number of mechanics for my fleet?” Although there is no quick answer that fits in all situations, there is a fairly straightforward methodology that can be used to estimate your requirements. It’s based on the premise that every fleet is different, and addresses the need to normalize the fleet to make it possible to apply industry benchmarks. In order to calculate your requirements, you need the following pieces of information:

• Fleet composition by vehicle class and number in each class

• Annual maintenance hours expended by vehicle class (or use an industry benchmark)

• Annual productive hours per mechanic (or use an industry benchmark)

With this information in hand, you simply follow these five steps:

1. Place vehicles in classifications and count them.

2. Count maintenance hours expended by vehicle classification for a given period of time.

3. Normalize the fleet by setting a base vehicle classification, and then rank all others relative to it based on maintenance hours expended.

4. Calculate vehicle equivalents using total vehicles in a class and the maintenance repair factor determined earlier.

5. Estimate necessary staffing levels.

Do the math

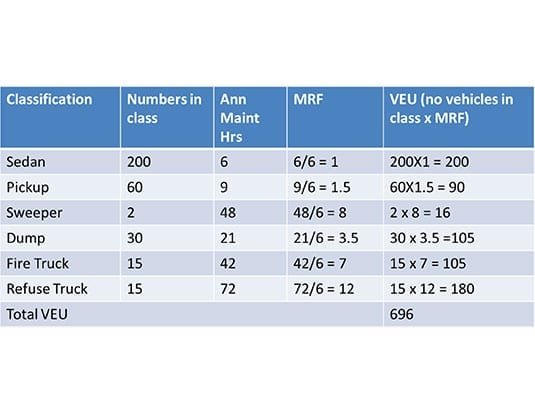

The table below illustrates a mixed fleet with six vehicle classes. The numbers of vehicles in each class are counted and shown. Next, the annual maintenance hours are reflected.

The Maintenance Repair Factor is calculated next. This is where you normalize the fleet using the least hours to maintain vehicle class as a 1. What this essentially means is, in this example, it takes seven times the effort to keep a fire truck on the road as it does for a sedan.

The final column shows the vehicle equivalency units in this fleet. In the end, this fleet of 322 vehicles is equivalent to a fleet of 696 sedans.

Vehicle equivalents

Now that we know how many vehicle equivalents we have in our fleet we can use our actual maintenance data, or an industry benchmark, to calculate what our annual workload is in hours. NAFA uses a benchmark of 6 hours per VEU (Vehicle Equivalency Unit), so the annual requirement for this fleet would be 4,176 hours (696 x 6).

How many mechanics do we need to accomplish 4,176 hours of work? A mechanic has a maximum of 2,080 hours annually on the job based on a 40-hour workweek. Of course, once you deduct everything that keeps a mechanic from actually turning a wrench you are probably left with only about 1,415 hours of potential wrench-turning time. Hours Required/Hours per Mechanic, or 4,176/1,415, would equal 2.95 mechanics.

A couple of additional considerations:

• You would not normally round up – it is more efficient to man to the lower number and outsource the additional work.

• When it comes to bays, NAFA recommends 1.5 bays per mechanic for lightduty vehicles and 2.5 for heavy duty.

• The number of productive hours per mechanic is influenced by vacation and sick days, so it can vary widely.

Many operational factors can influence the average hours required to keep a sedan on the road, including the age of the fleet and the operating environment. This is a practical tool offered by NAFA in their Maintenance Management module. It is a relatively easy test that most fleet managers can calculate themselves to see how their shops measure up.