General Motors says it is using new, advanced software design technology to introduce the next generation of vehicle lightweighting.

The technology is seen as key to developing efficient and lighter alternative propulsion and zero emission vehicles.

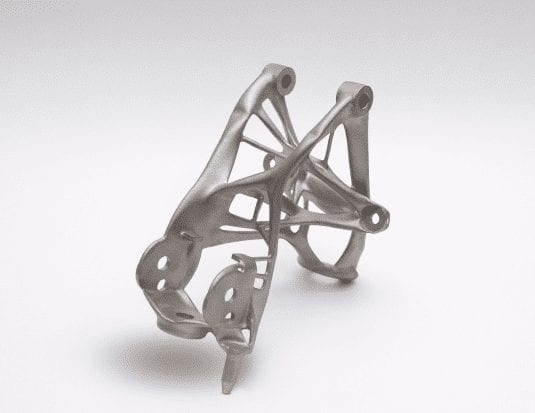

GM is the first automaker in North America to use new generative design software technology from Bay Area-based software company Autodesk. It uses cloud computing and AI-based algorithms to rapidly explore multiple permutations of a part design, generating hundreds of high-performance, often organic-looking geometric design options based on goals and parameters set by the user, such as weight, strength, material choice, fabrication method, and more. The user then determines the best part design option.

“This disruptive technology provides tremendous advancements in how we can design and develop components for our future vehicles to make them lighter and more efficient, said GM Vice President Ken Kelzer, Global Vehicle Components and Subsystems. “When we pair the design technology with manufacturing advancements such as 3D printing, our approach to vehicle development is completely transformed and is fundamentally different to co-create with the computer in ways we simply couldn’t have imagined before.”

As part of a multi-year alliance focused on innovation, GM and Autodesk will collaborate on projects involving generative design, additive manufacturing, and materials science. Executives and engineers from the two companies will participate in a series of onsite engagements to exchange ideas, learnings, and expertise. GM also has on-demand access to Autodesk’s full portfolio of software and technical specialists.

“Generative design is the future of manufacturing, and GM is a pioneer in using it to lightweight their future vehicles,” said Scott Reese, Autodesk Senior Vice President for Manufacturing and Construction Products. “Generative technologies fundamentally change how engineering work is done because the manufacturing process is built into design options from the start. GM engineers will be able to explore hundreds of ready-to-be-manufactured, high-performance design options faster than they were able to validate a single design the old way.”

Since 2016, GM has launched 14 new vehicle models with a total mass reduction of more than 2267 kg (5,000 lbs.), or more than 159 kg (350 lbs.) per vehicle. Most of the weight reduction is a result of material and technology advancements. Of those models, more than half of the vehicles shed 136 kg (300 lbs.) or more including the 2019 Chevy Silverado, which reduced mass by up to 204 kg (450 lbs.).