Technology could render the collision repair process itself obsolete.

Last week, I had a conversation with collision industry thought leader. Our discussion focused on the evolving complexity in vehicle construction and the impact it’s having on the repair process.

A decade ago, even five years ago, the notion of having to pre-scan the vehicle before even beginning the repair process, or having to ensure the shop had precision measuring equipment, as well as brand and even model specific aluminum and mixed material welders, sanders, dent repair stations and extraction systems was almost unheard of.

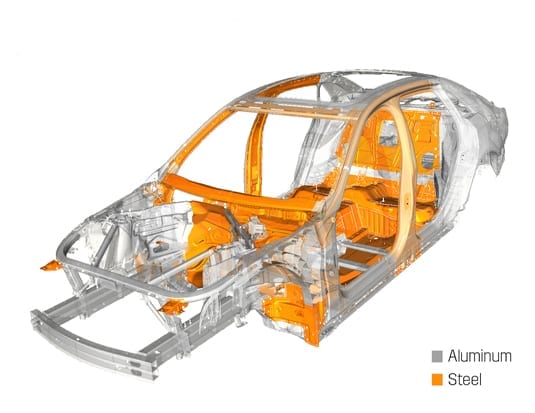

Today, the level of investment required just to perform repairs to OEM specifications can be staggering and with vehicle construction and substrates changing so rapidly, some shops are having to make major equipment investments every 2-3 years instead of 5-10 years. Mixed material structures that use aluminum, high-strength steel, boron steel—even carbon fibre—are becoming the norm rather than the exception, even on mass-market vehicles. At the same time, technology such as drive by wire throttle, steering assist, braking assist, lane keeping assist, adaptive cruise control, blind spot monitoring, collision warning require specialized training and scanning, not to mention significant cost if sensors need to be replaced and or/reset.

The question then becomes, how feasible is the repair process and at what point does it become easier to simply write-off the vehicle instead of trying to fix it?

Statistics across North America indicate that average repair costs are increasing significantly related to replacement value. As a result, insurance carriers are writing-off growing numbers of late model vehicles simply because the cost to repair them exceeds the book value.

Additionally, in many cases, it’s becoming more feasibly to replace parts than trying to repair them, which is also driving up the cost of repairs. And it’s all being driven by government legislation on vehicle safety and fuel economy.

Since the early 1970s, regulators have become virtually obsessed with the idea of auto safety and emissions requirements. These mandates have put enormous pressure on OEMs to deliver vehicles that are less polluting, safer and more reliable. Yet it seems there comes a point where the gains in safety, emissions and fuel economy become negligible at best. Compared to the 1970s, today’s emissions reductions are in the 1-2 percentile range, while the standards proposed by Corporate Average Fuel Economy regulations are becoming very challenging—if not virtually impossible—for automakers to meet within the timeframe required.

We talk about electric vehicles and even autonomous vehicles solving many of our existing transportation issues in the coming decades but these tend to shift the problem from one area to another. Electric vehicles need an energy source from which to draw their power, while AVs, although statistically having the potential to reduce collisions will likely follow the same pattern as air accidents, namely that when disaster does strike, it is likely to be far bigger and more widespread (a technology or software malfunction has the potential to cause multiple collisions at once).

And if by that stage, vehicle complexity has increased so much that the purchase price or value of the vehicle is exceeded by the repair cost, will it even make sense to have facilities designed to repair vehicles? Will it follow the appliance market where instead of fixing your washer, you simply throw it away and get another one.

I liken the advancement in vehicle technology today as similar to aviation technology in the 1950s and 1960s. Today, you can still see many World War II vintage aircraft flying at airshows. When was the last time you saw a privately owned airworthy F-104 Starfighter or F-4 Phantom II thrilling the crowd?